With the Covid-19 emergency makers around the world start making safety masks to help health staff and personal use, different models and designs of safety masks are all over the web, many are for 3D printing, some are for laser, a few for CNC.

The mask needs 4 basic components

The Support

The shield

Cushion for using them for long periods of time

Holding mechanism

Because of the diverse materials used sometimes is difficult to make this masks to be strong enough to be reusable, and most of the times this are disposable and single use.

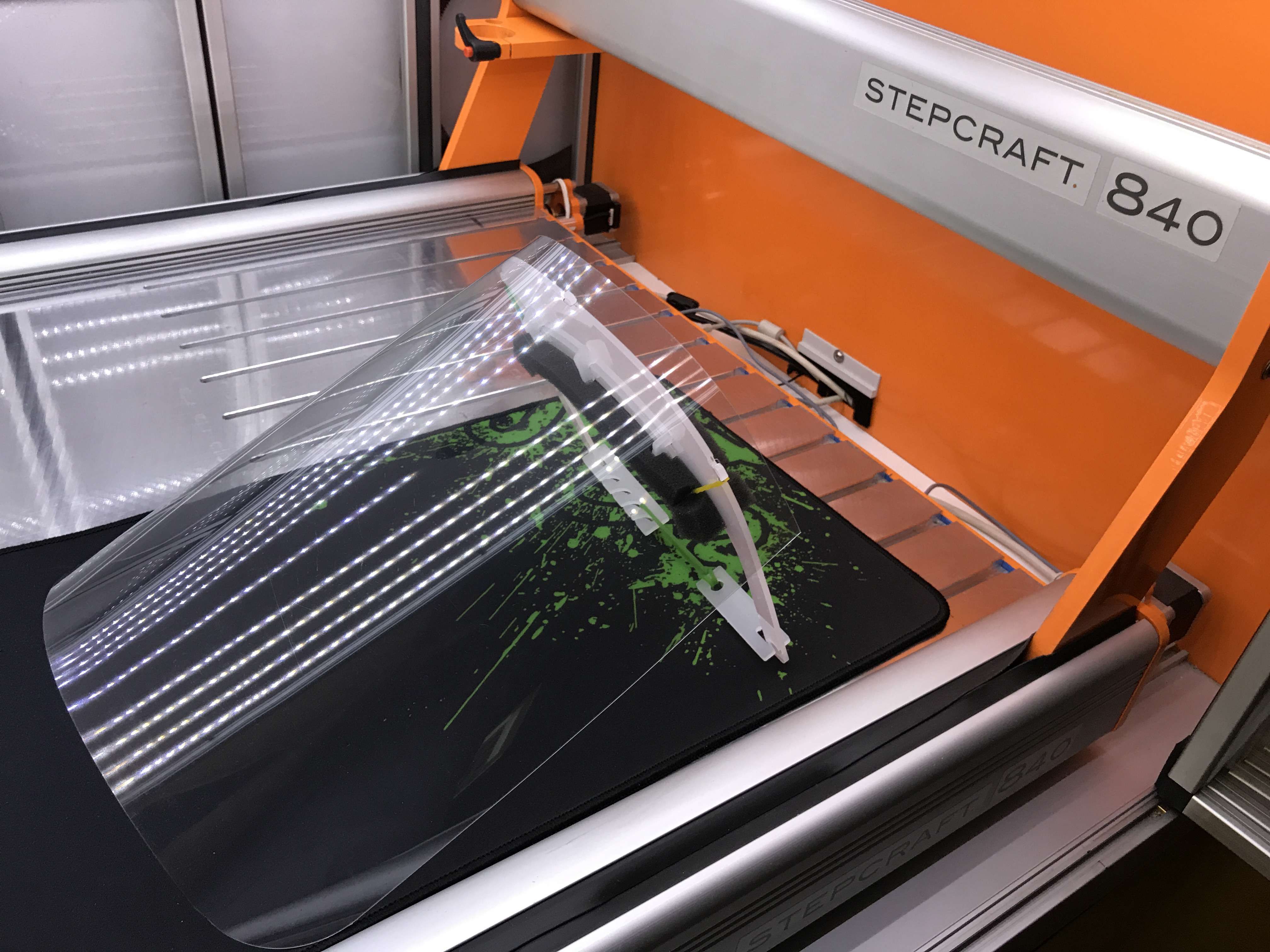

Thinking on this we decide to make a design to have all this components and using the Stepcraft versatility of using different tools and materials, making it very easy to assemble and without the need of any type of glues. The use of rubber bands give the benefit to change them all the times without been expensive.

What we use

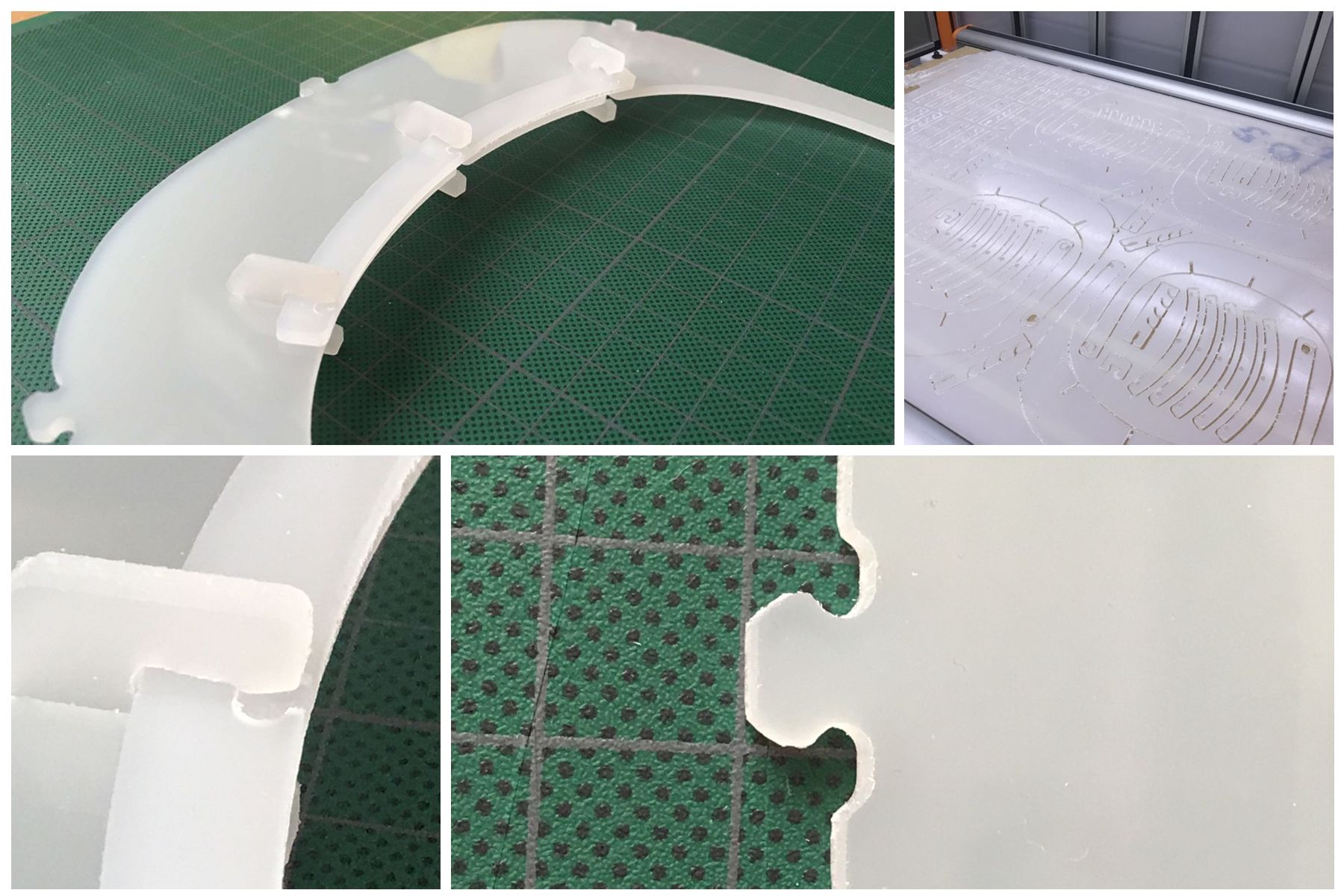

The support

Cut with the Spindle and made with 3mm acrylic, this material can get disinfected over and over, made with 6 parts and very easy to assemble.

Using a 2mm O flute endmill to obtain the bests details

Using a Feedrate of 19mm/sec and a plunge of 10mm/sec at 17,000 RPM

The design can be milled with a 1/8 endmill too (for thicker materials)

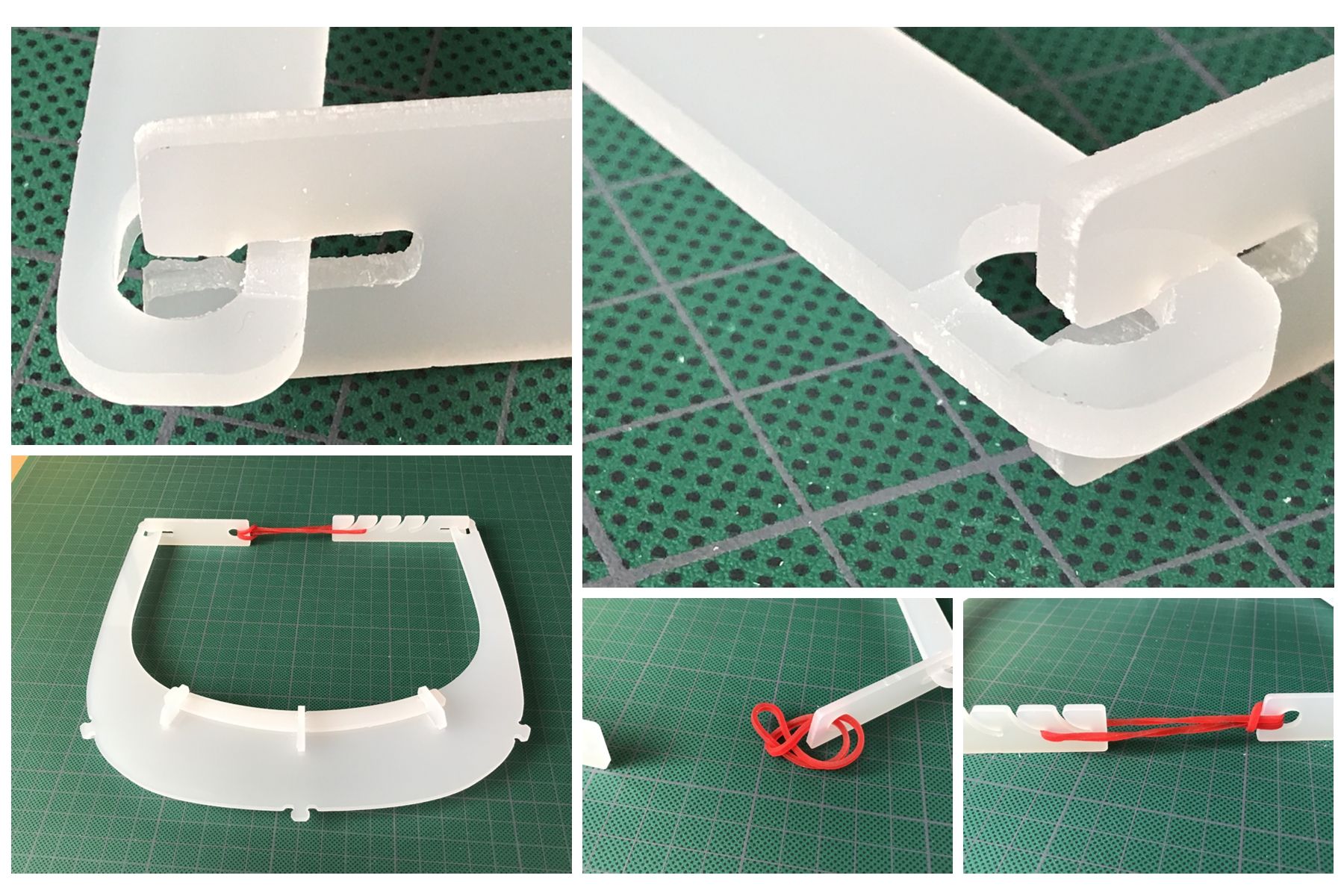

The assembly is done with a small clips that fit into pockets of the support, it also have pockets to make the hinge assembly easy and avoid clip off.

And a clip type to hold the shield

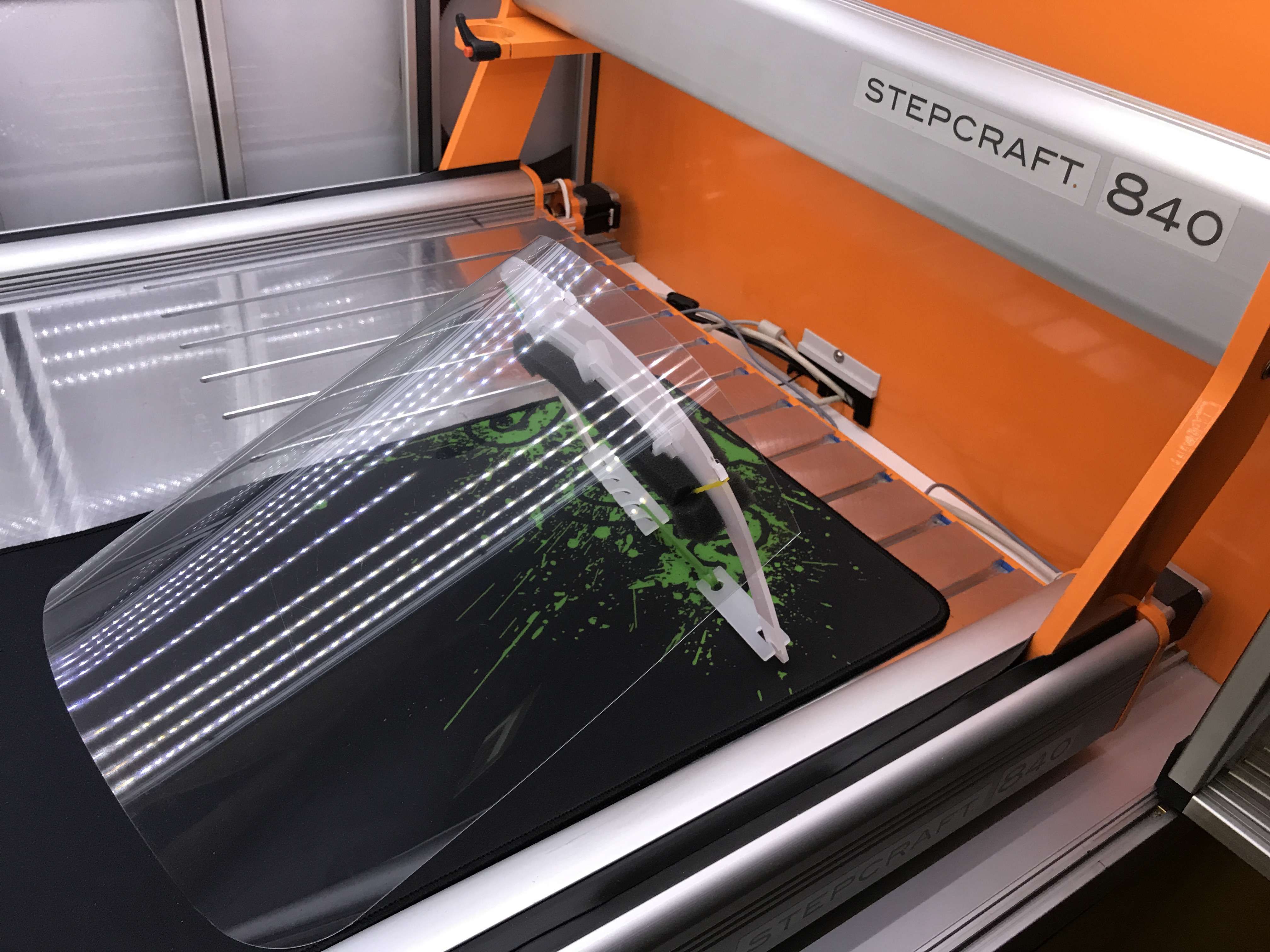

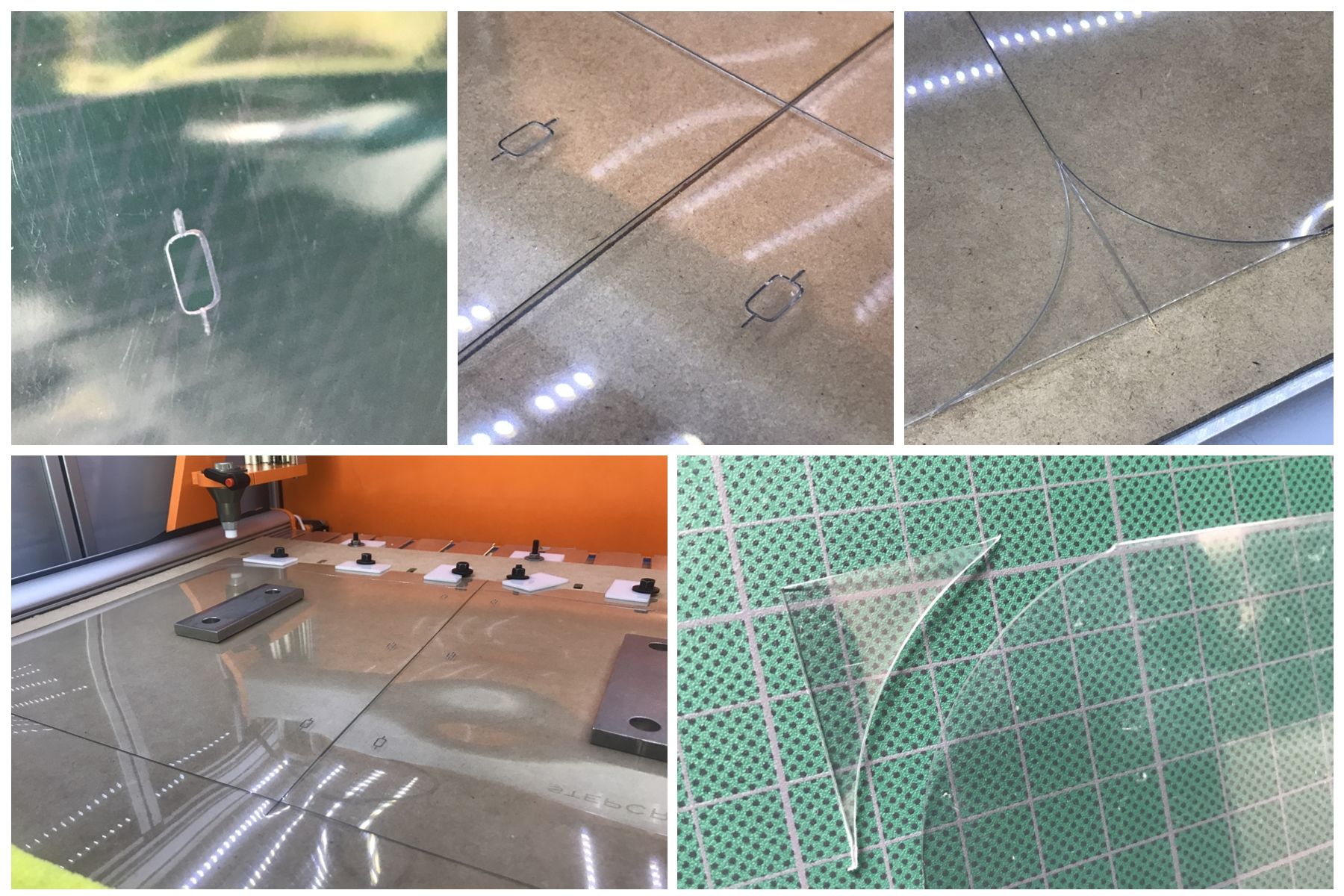

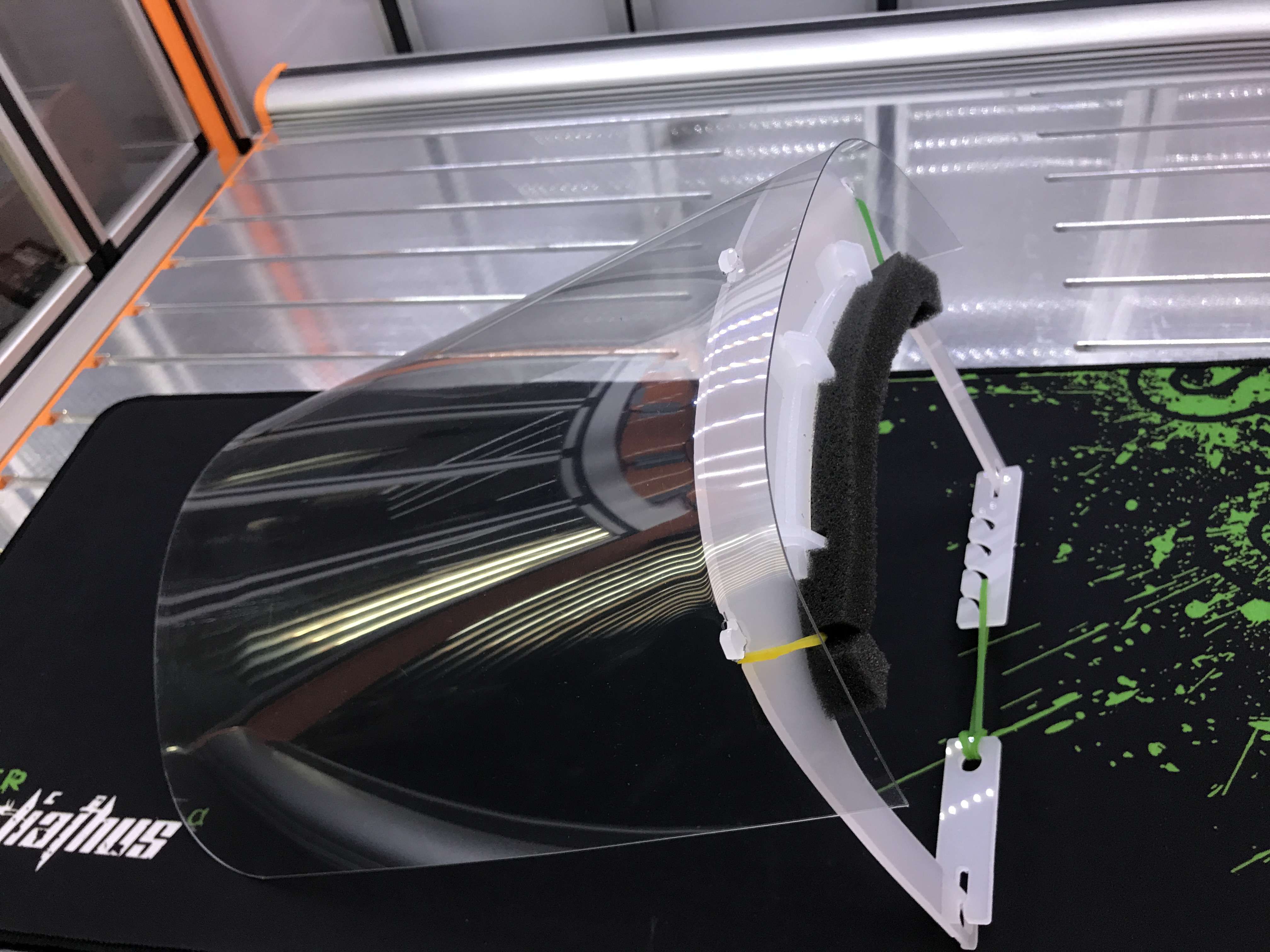

The shield

Cut with the drag knife, using PetG 20 Cal (0.5mm thick), this material is also strong and easy to clean and disinfect for several times too.

Setup a special support table to fix the Pet sheet and cutting 2 sides at the same time this make the waste of material to the minimum

Using a feedrate of 25mm/sec and 15mm/sec plunge

The important part of this toolpath is to make the dragnife movement go on certain directions to avoid damaging the blade

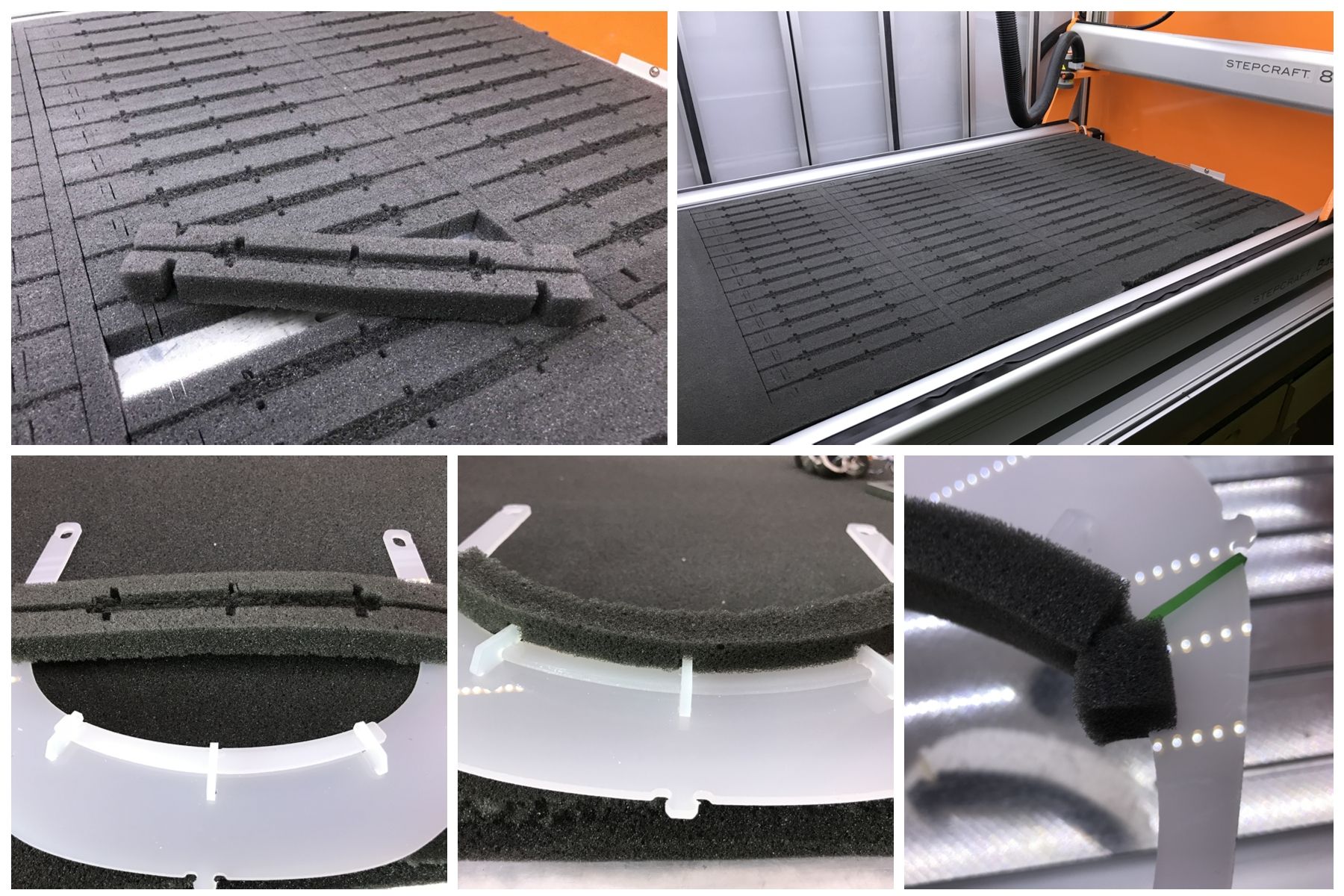

The cushion

Cut with the Laser to obtain a perfect fit on the design, the cushion foam is hold by rubber bands to make it easy to remove and wash or disinfected, and if its the case replace it with a new one.

The pocket is made with a quick engrave option with a .35 space and hatch of 90 degree if its vertical, and a setup of 35mm/sec feedrate

This leave a very small amount of material inside the pocket but because its very fine when the cushion is washed and assembled it dissapears. it can be done with less space and will not leave any residual material.

The cut have a setting of 4mm/sec for a 18mm tick foam.

The holding mechanism

Cut with the Spindle and made out of Acrylic, this system acts like a hinge and can be adjusted to fit any size of head with 2 parts and a rubber band.

The pocket cut on the outside of the support make it easy to assemble but when its in use it wont disassemble.

Using a 2mm O flute endmill to obtain the bests details

Using a Feedrate of 19mm/sec and a plunge of 10mm/sec at 17,000 RPM

The design can be milled with a 1/8 endmill too (for thicker materials)

Files

Download files for Stepcraft CNC (Cut 2D) / DXF

Files included on the archive:

Acrylic Cut.crv

Acrylic Cut 3 versions.dxf

Acrylic Nesting Example.dxf

Cushion Foam Cut.crv

Cushion Foam Cut.dxf

PetG-Clear Cut.crv

PetG-Clear Cut.dxf

Download Link: Safety_Masks_for_Stepcraft_CNC.zip

Assembly Video

How to assemble the safety mask

Simple instructional video showing how to assemble all the parts

Making Re-usable Safety Masks