CNC Milling machine FOR WORKSHOP PROfessionals

STEPCRAFT M-SERIES

You can't get more freedom! The STEPCRAFT M-Series is truly the most versatile CNC system in the world. With Freestyle Milling™ and two different machine table heights, the CNC system offers features never seen before. You can easily mill into large sheet materials, wooden tables, or even directly on to floors! The M-Series CNC router systems are designed to run 24/7 in production environments, workshops, labs, schools, and more. STEPCRAFT is known for its multi-function capabilities and the M-Series is completely compatible with all STEPCRAFT attachments to expand your capabilities from milling to 3D printing, lasering, plotting, cutting and much more.

CNC Milling Machine for large and small CNC projects

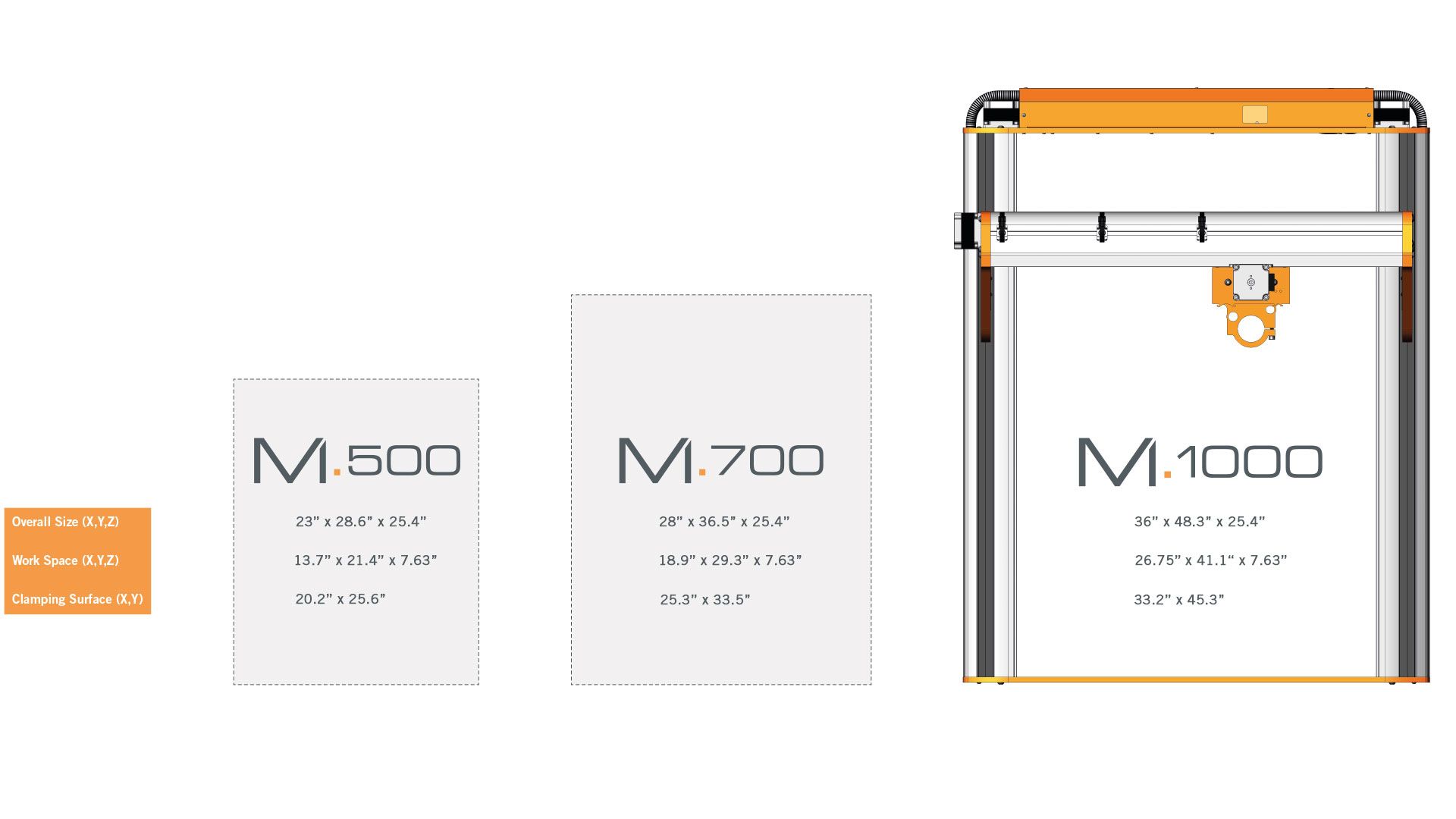

The perfect size for every CNC project! The M-Series CNC systems offer lots of space to make just about any project that you dream up no matter the size. If you can not fit the material on the CNC, then you can put the CNC on the material. The M-Series is offered in 3 different size models: M.500, M.700, and M.1000 allowing you to choose the perfect size for your needs. The M-Series CNC systems come completely assembled and ready-to-run with the option to purchase in kit-form with a slightly lower cost.

Unique in the world - Freestyle Milling TM

Milling, laser engraving, cutting, or carving — where and how you want! The

STEPCRAFT

M-Series is the only CNC machine in the world that enables real Freestyle

Milling™!

Place the machine exactly where it is needed. The optional powerful Vacuum Rails

will attach the CNC router firmly with powerful suction the project's surface. Thanks to the completely removable machine table, you can engrave

logos

, patterns, and designs into floors, furniture, sheet material, or permanently installed workpiece materials. The numerous possible mobile applications make the

STEPCRAFT

M-Series the most versatile CNC machine in the world - protected as a registered utility model by the Germany Patent and Trademark office.

Finally, a CNC system that has no limitation to the project size. The STEPCRAFT M-Series allows you to save the money for a larger format CNC mill as well as space in your shop. You can simply remove the machine bed and mill directly onto the material beneath the machine.

Bring the machine to your project! The M-Series CNC systems allow you to mill in existing items like furniture, cabinets, or floors. Items that would be out of reach for a typical CNC can be successfully customized thanks to Freestyle Milling ™.

Powerfully hold in place! The optional vacuum rails can be easily attached to your M-Series CNC and using the suction from a common shop vac, the resulting vacuum pressure will securely hold the machine in position while milling.

Innovation on every Level

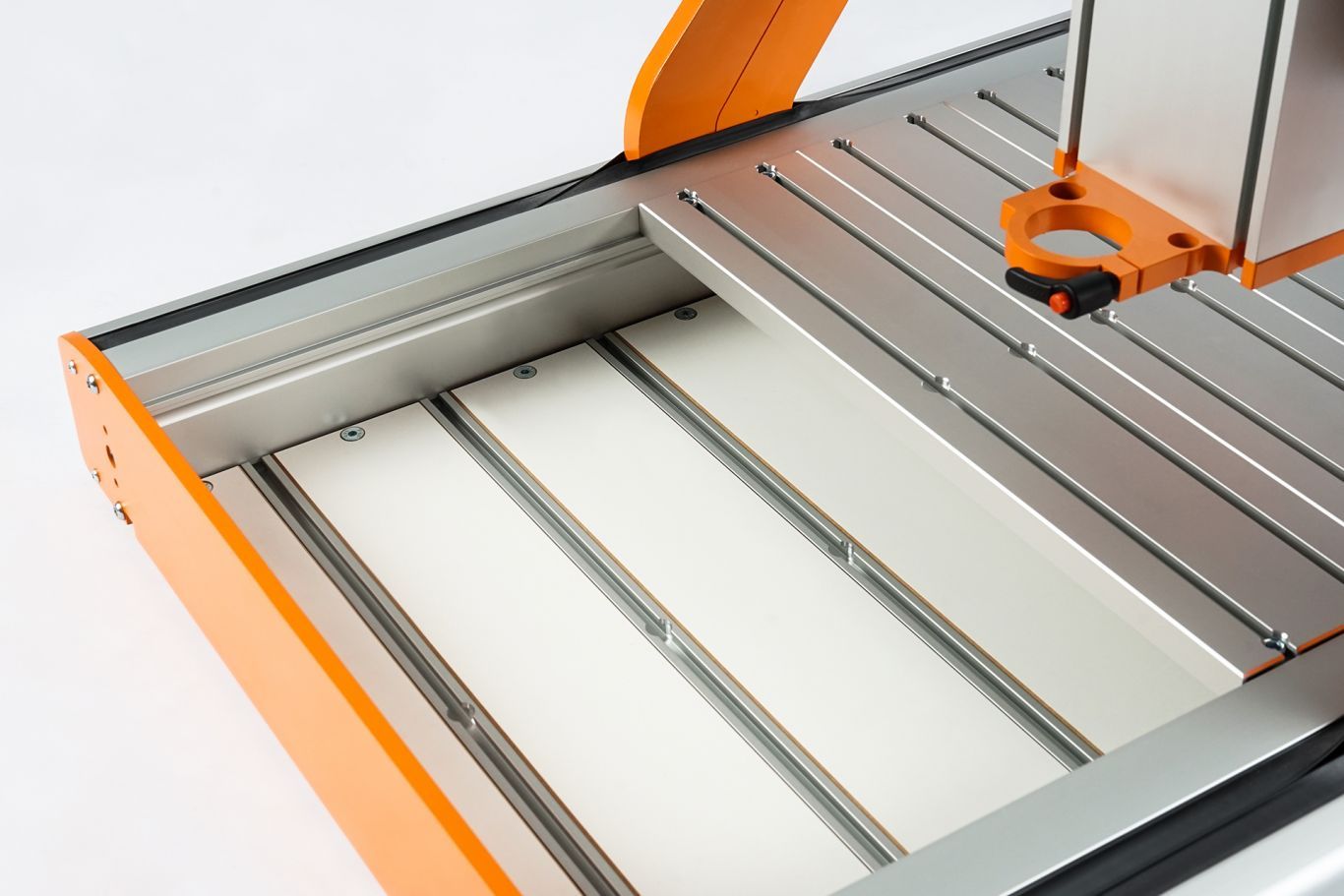

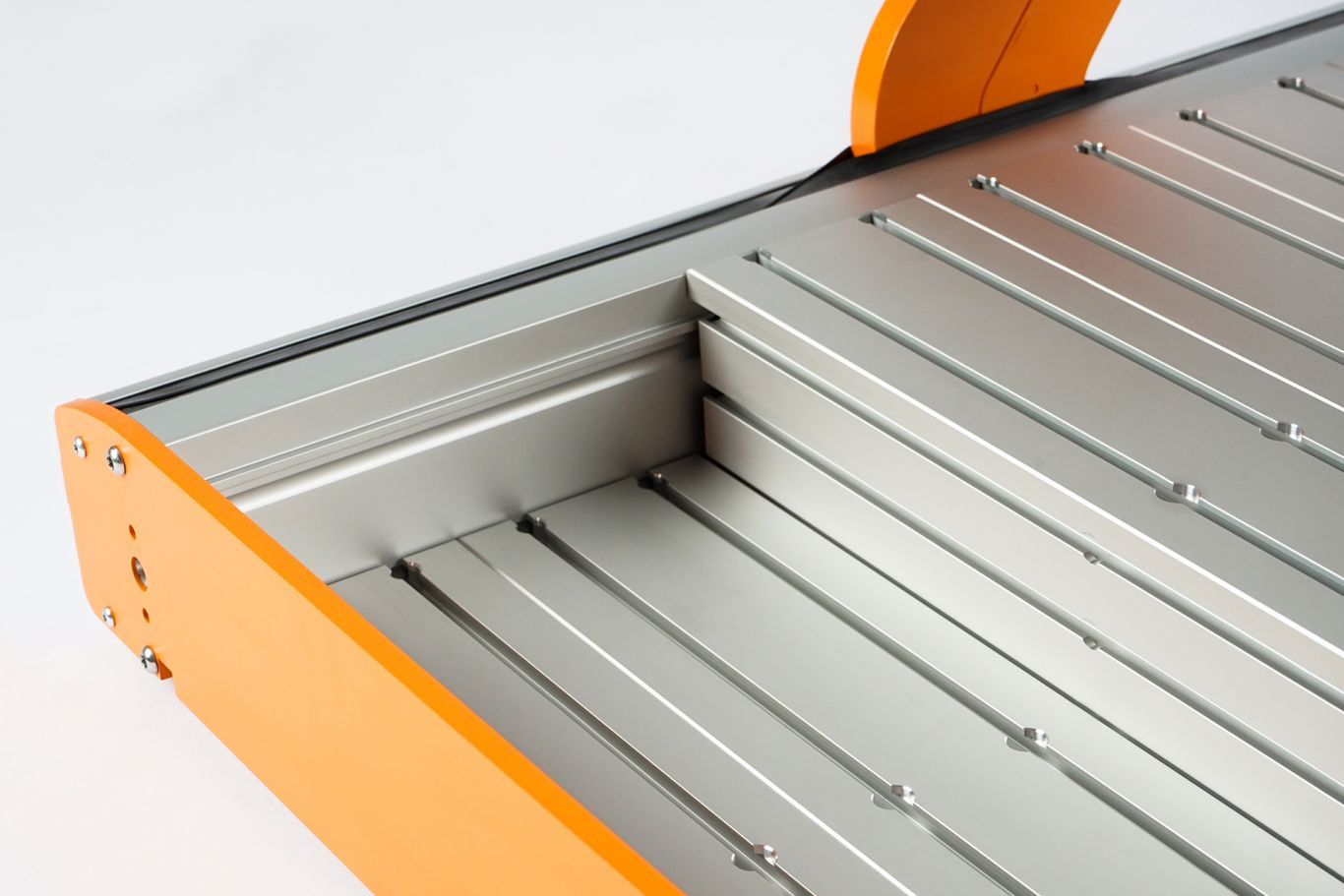

The STEPCRAFT M-Series offers many new possibilities for CNC machining. There are two different table heights that allow you an additional 2.75" of Z height - more than any other machine in its class. A 90-degree Vertical Clamping Fixture can be added to allow vertical clamping and machining of workpieces - perfect for dovetail and other cabinet joints. Tables are available in MDF with aluminum t-tracks or all-aluminum to give you the most flexibility of materials that you can process.

Two Machine Table Heights

- The perfect amount of Z travel for every workpiece

- The linear Y-axis frame profiles have two different table mounting positions.

- Perfectly suited for CNC processing of taller workpieces

- Quick and easy installation and removal thanks to EasyFix locking nuts

- Allows for permanent installation of CNC accessories (4th Axis)

Machine Table with T-Slots

- Quick and easy clamping of CNC workpieces

- MDF machine table with aluminum T-slots

- Easy to reconfigure the machine table elements

- Can be used on both machine table elements

- Aluminum T-slot table optionally available

90° Vertical Clamping Fixture

- Quickly add to the machine when needed

- Five T-slots for flexible clamping

- 90° Vertical Clamping Fixture is ideal for vertical milling, such as with dovetails

- Made from aluminum for maximum rigidity

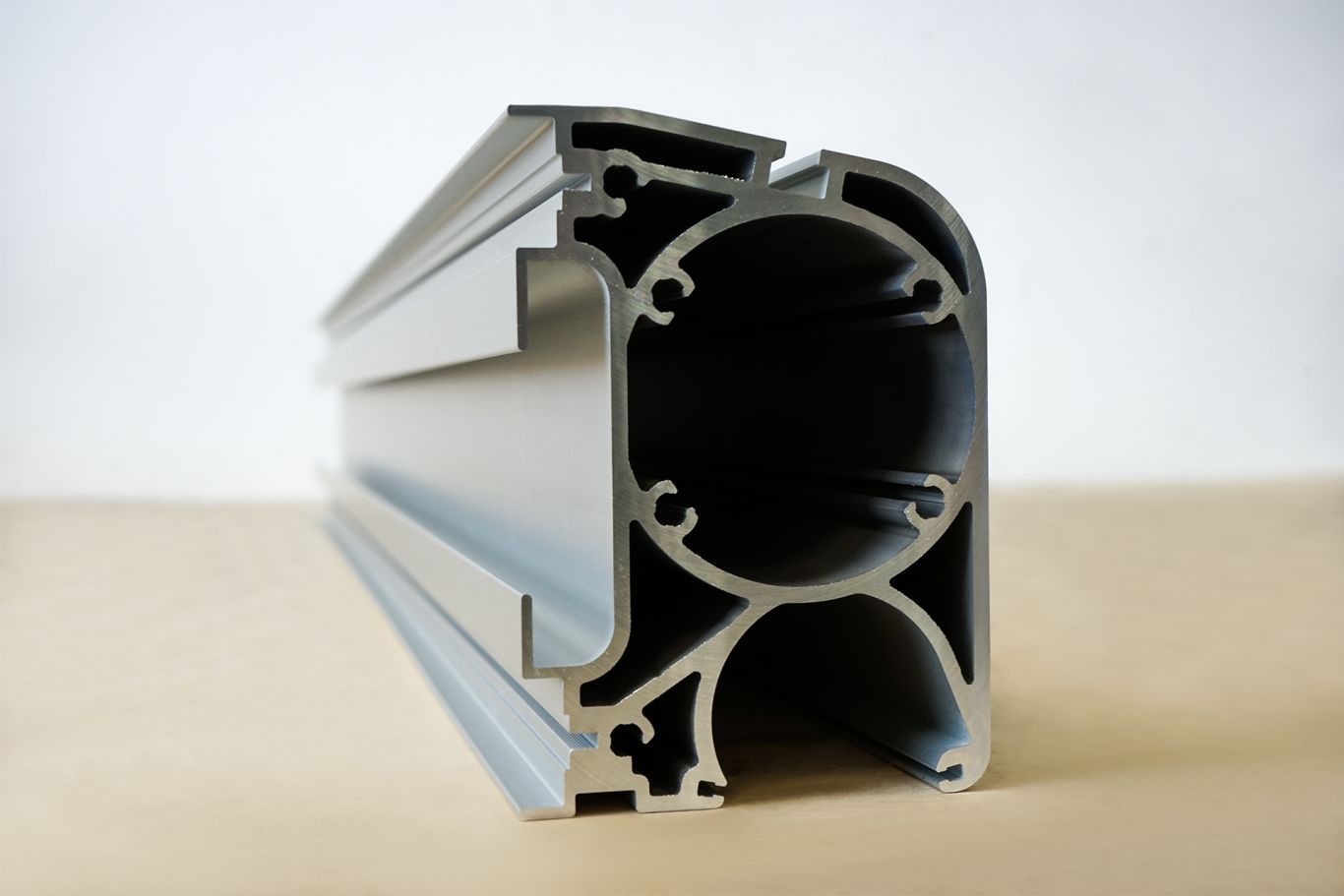

Highly engineered CNC Technology

Well-thought-out CNC technology is required for high-precision results. The STECPRAFT M-Series works precisely and reliably thanks to the innovative extruded frame components and the Bosch Rexroth precision linear guides. The small Flexi Guides™ ensure neat and clean cable routing while the optional Semi-Closed Loop System™ offers additional protection of your workpieces.

Very Rigid X-profile

The high-strength X-profile of the STEPCRAFT M-Series sets new standards with regards to the stability and design of CNC machines. The innovative construction design ensures high force absorption and the even distribution of forces within the axis. An extremely high torsional stiffness is achieved this way. The engineered extruded aluminum construction components of the CNC axis, frame, and gantry components offer a highly stable profile design hat would not be possible with steel. An innovation from STEPCRAFT, which is protected as a registered utility model by the German Patent and Trademark Office.

SEMI CLOSED-LOOP SYSTEM™

Ball Bearing Guide

Flexi Guides TM

No cable clutter! Each machine of the STEPCRAFT M-Series comes with three Flexi Guides™. The white plastic holders serve to securely guide cables and tubes of tools and accessories.

The Flexi Guides™ can be easily positioned and fastened in the T-slot of the X-axis.

Powerful Drive

The STEPCRAFT M-Series operates with maximum precision and accuracy and runs quietly and vibration-free. You can choose between the standard igus® dryspin threaded lead screw or precision HIWIN® ball screws. The powerful 23 motors drive the machine powerfully through a wide variety of materials.

igus® dryspin lead screws

- Specially developed for screw drives

- Based upon wear-resistant igus® high-performance polymers

- 5 times longer service life with higher efficiency

- Low-noise and vibration-free

- Driven by powerful Nema 23 stepper motors on both sides of the Y-axis

- Adjustable lead screw nuts minimize backlash

precision HIWIN® Ball Screws

- Optionally available instead of standard igus® dryspin threaded lead screws

- High ease of movement

- Balls roll in an endless loop between the threaded screw and nut via the ball return system providing zero backlash

- For maximum precision and accuracy

CNC Tools - Simply makes you more creative

Turn your STEPCRAFT M-Series CNC system from a milling machine into a 3D printer, a CNC laser, a plotter, or a tangential knife. With over 12 various attachments, you can machine wood, aluminum, brass, cardboard, foil, cardboard, and more - all on once machine... in a variety of ways. All STEPCRAFT CNC tools can be easily and quickly installed on the M-Series machines, which not only makes you more creative but saves you money by not needing additional machines.

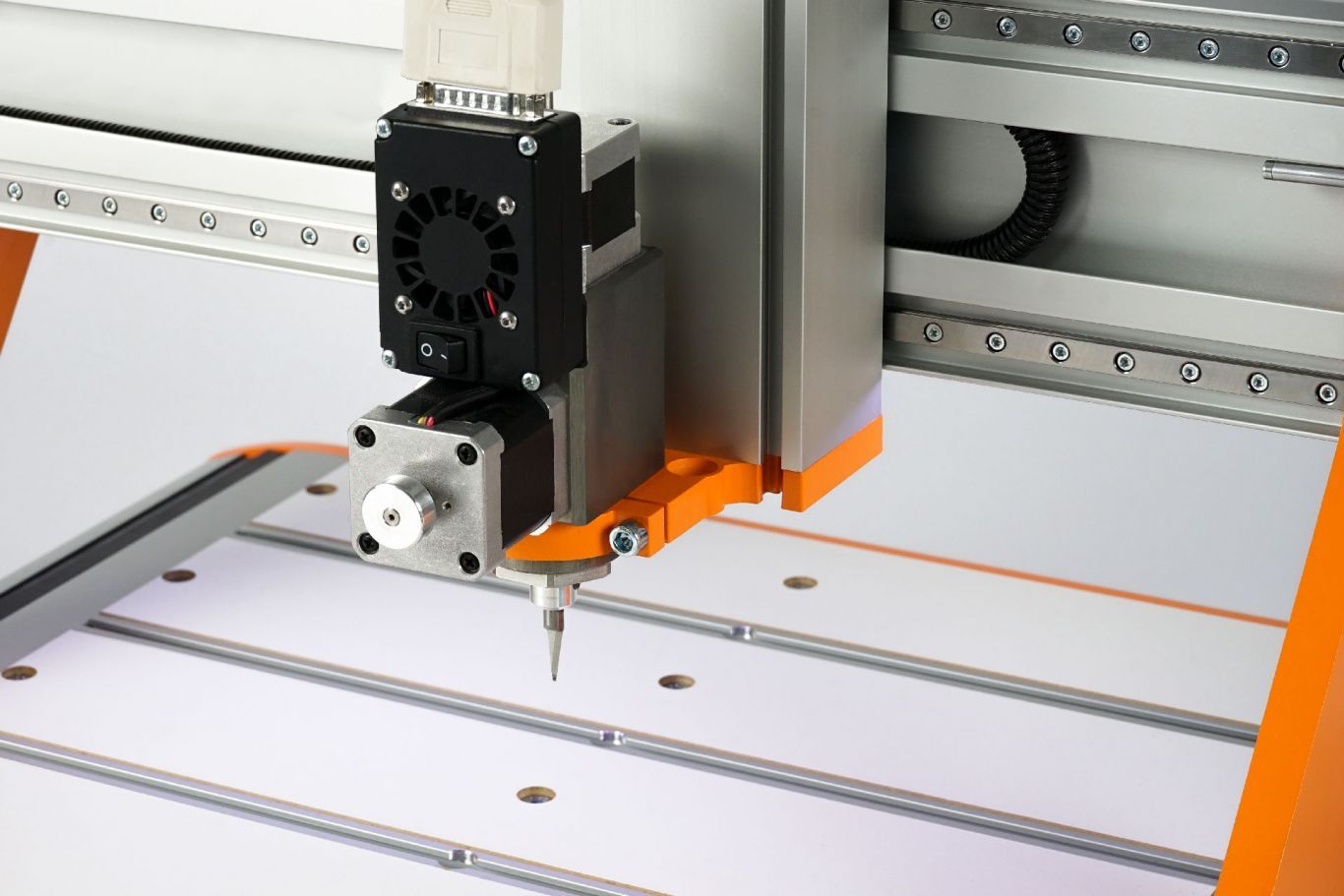

Milling Spindle

STEPCRAFT's powerful milling spindles give you the ability to create high precision workpieces from sheet material like MDF, plywood, Plexiglas®, sign substrates, wood, aluminum, carbon and much more.

Do you need help selecting a suitable CNC spindle for your needs? Please visit How to find the perfect Spindle Motor and you will find all the information on our HF Spindle, CNC Tool Changer, or the MM-1000 spindles.

oscillating Tangential Knife

Perfect cuts with the OTK, even with small fonts and contours! The Oscillating Tangential Knife cuts with high precision and rotates in the respective cutting direction. The OTK makes it possible to cut materials that you could never before on a CNC machine. Materials like leather, foam, rubber, cardboard, and more cut easily and cleanly. Think of all the possibilities that you can achieve.

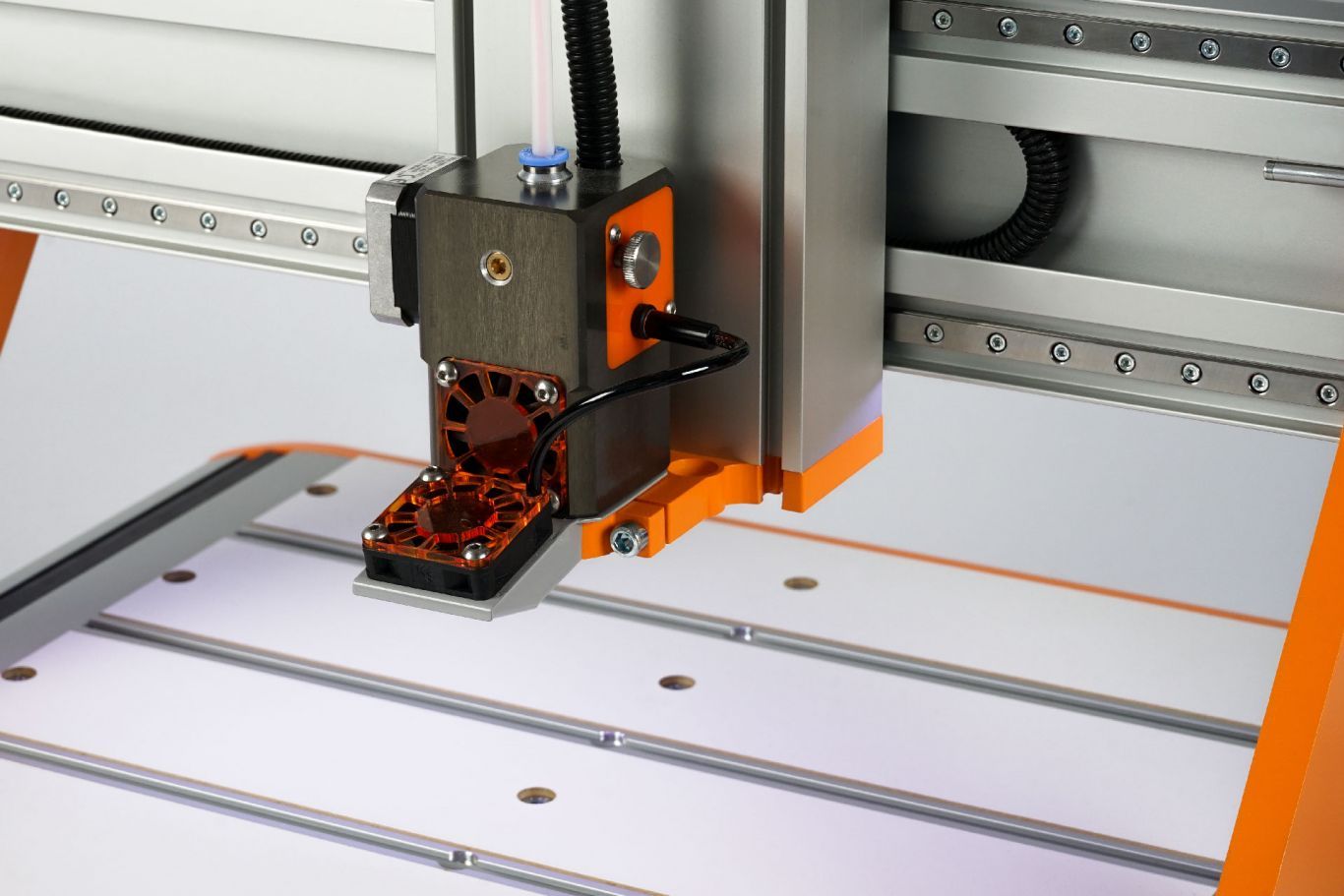

3D Printer

The 3D Print Head opens up the world of additive manufacturing with your STEPCRAFT M-Series CNC system. Using a wide variety of plastic-based materials, you can build up parts with complex shapes that would otherwise be impossible to machine in a traditional CNC environment. The option component fan makes even small, pointed geometries possible.

CNC Laser

Engrave without contact! It is not necessary to clamp the workpiece when working with the DL445 3 Watt Laser Engraving Head. Depending on the material, you can even do smaller cutting jobs with the CNC Laser. Engrave projects with font engravings, halftone images, or puzzles with ease.

Drag Knife

The CNC Drag Knife precisely cuts a wide variety of materials like sheet vinyl to make self-adhering decals or cut paper and foils to make your M-Series CNC the perfect crafter's system.

Available in Ready-to-run or CNC Kit

READY-TO-RUN CNC SYSTEM

Start right away with your CNC projects! The STEPCRAFT M-Series CNC systems will come to you fully ready-to-run and test from our facility in Torrington, Connecticut USA. Our highly experienced CNC experts will take the utmost care to ensure that your M-Series CNC is built and tested with the quality control that you would expect from a German-Engineered and American-Built machine. You simply have to unpack the machine, plug it in, add your attachments, and install the software - you can be up and cutting in less than an hour.

Benefits of the pre-assembled CNC Router::

- Get started immediately

- Save time

- Perfectly assembled by STEPCRAFT technicians

CNC KIT

Assembling a CNC router is not rocket science and we do everything we can to make the process as simple as possible. We deliver all the necessary components securely packaged in a custom styrofoam core. With our assembly manual and video support, you can have your M-Series CNC up and running in just a few hours. By opting for a CNC Kit you can save money with the added benefit of knowing every detail on your CNC system.

Benefits of the DIY CNC kit:

- Save money

- Know every detail of your CNC router machine

- Carry out maintenance work independently

- Enjoy building

M-Series: Find the best CNC Router for your needs

Find the perfect CNC milling machine for your application. In the chart below we have put together all technical data for the M.500, M.700, and M.1000 for you. You can find out more information about the various milling machines in our shop.

Any questions? We are always happy to provide you with personal assistance. Simply send us an email at info@stepcraft.us or call us at 203-556-1856.

| STEPCRAFT M.500 | STEPCRAFT M.700 | STEPCRAFT M.1000 | |

|---|---|---|---|

| Z Axis Clearance | 5.21/8.07" (135/205 mm) | ||

| Repeatability | +/- 0.0009" (0.025 mm) (with optional HIWIN® ball screws: +/- 0.0005"/0.015 mm) |

||

| Programmable Resolution | 0.0002" (0.00625 mm) | ||

| Backlash | 0.0019 (0.05 mm) (with optional HIWIN® ball screws: ) 0.0012"/0.03 mm |

||

| Maximum Speed in Diagonal Travel X-Y | 284 in/min (120 mm/s) | ||

| Spindle (Lead Screw) | igus® dryspin 12 x 5 mm (optional: HIWIN® ball screws 12 x 5 mm) | ||

| Linear Guide | Bosch Rexroth ball bearing guide | ||

| Drive | Stepper motors: Sanyo-Denki NEMA 23 | ||

| Tool Holder | 43 mm clamping diameter (Euro neck, optional smaller diameters) | ||

| Weight | 61.7 lbs (28.0 kg) | 77.1 lbs (35.0 kg) | 92.3 lbs (42.0 kg) |

| Input Voltage | 110-240V (comes standard for 110V/60h) | ||

| Output Voltage | 24 - 30 V | ||

| Power Consumption | 180 W | ||

| Interface | USB / Parallel (LPT1) / Network RJ-45 | ||