The spouse has taken the kids for an afternoon getaway with the inlaws. The dog is fast asleep on the couch and your boss has promised not to bother you for the weekend. Here it is, that once in a blue moon opportunity to finally fire up that Multi-Function CNC machine and start creating! You can hardly contain your excitement as you run to the garage, USB in hand ready to change the world with your new design! The Z-Axis sings its sweet song as it moves for the first time in ages, followed swiftly by the X and Y. The clamps are tightened and anxiously awaiting the buzz of the spindle on the freshly planed baltic birch. This is it! The sun gleams through the window and a rainbow suddenly shoots across the room as you do it! "Cycle Start". Birds are singing and you can just about see a coconut drink on its way. Then ... it happens. Somewhere, someway, somehow your machine has decided that it wanted to cut an inch and a half to the left of where it was instructed. Ecstasy shattered. Your machine has experienced the dreaded ... loss of steps.

My name is Greg and as the Support Manager here at Stepcraft, I know firsthand how frustrating and debilitating it can be to exprience losing steps on your CNC machine. That is why I am here to tell you ... DON'T PANIC! In this article I will share with you the reasons you may be losing steps and the keys to getting back up in running in no time!

What is Losing Steps?

Most modern day CNC machines are powered on each axis by Stepper Motors. In the most basic of terms, these are very powerful motors that constantly "count" the steps they take as they turn. Step 1, Step 2, Step 3, Step 4, etc. The important thing to note is that there are no feedback loops on these motors, or anything that tells the motor what is actually happening vs. what is was told to do. If the motor was instructed to go to position X, which may be 6 steps, it will travel until it has counted 6 steps. Because there is no active feedback, if something happens along the way that physically stops the motor from moving, the software is still counting Step 5, Step 6, when in reality it may be PHYSICALLY STUCK on Step 3. Now, the software "thinks" it has reached Step 6, or Position X when in reality it is still back on Step 3, never having reached Position X. Because the software "thinks" it is at one position, it will carry out the G Code from that position, never "knowing" that it is actually at another position. This is what is called Losing Steps and it stinks. The major signs that you have lost steps are ...

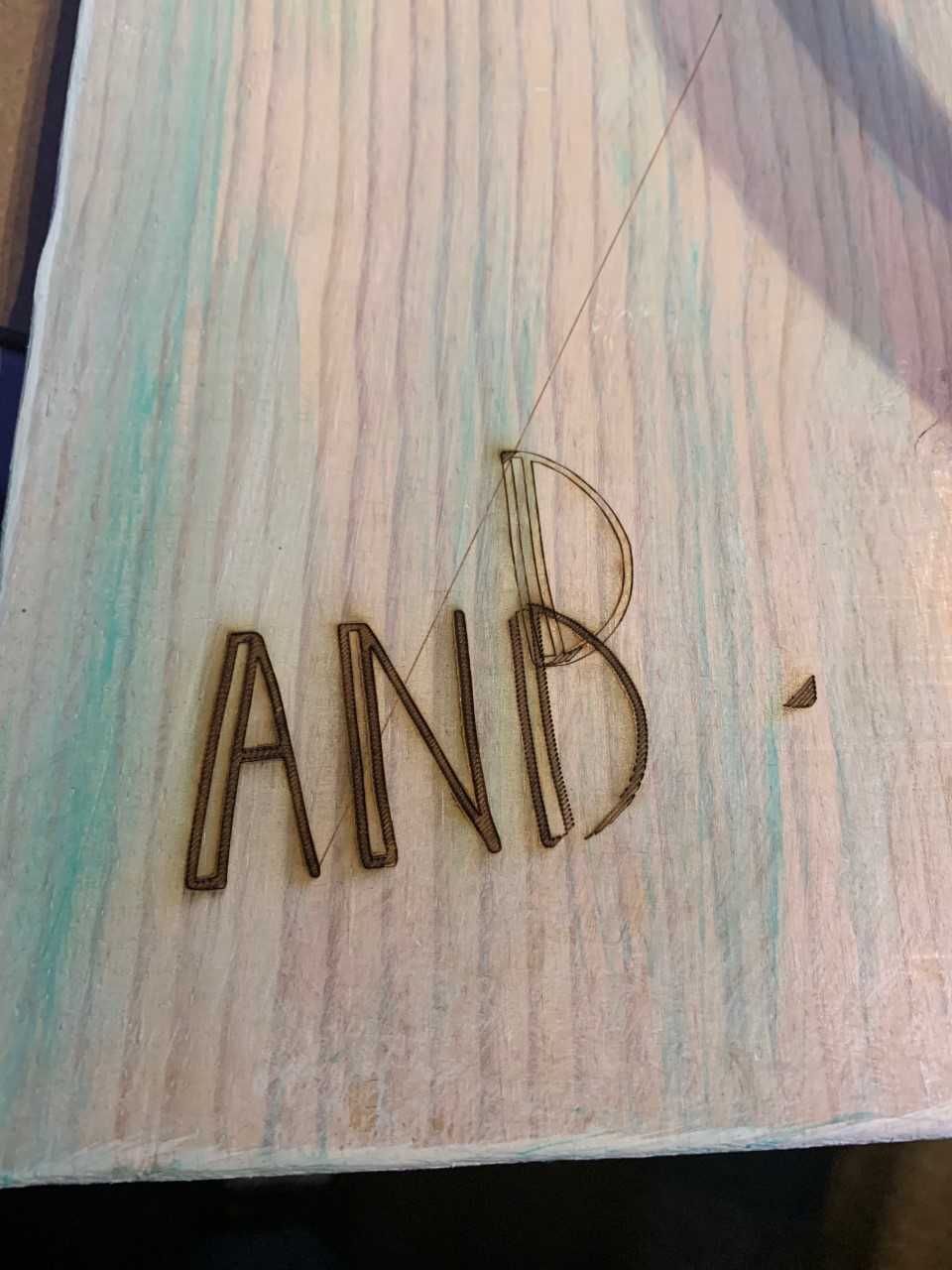

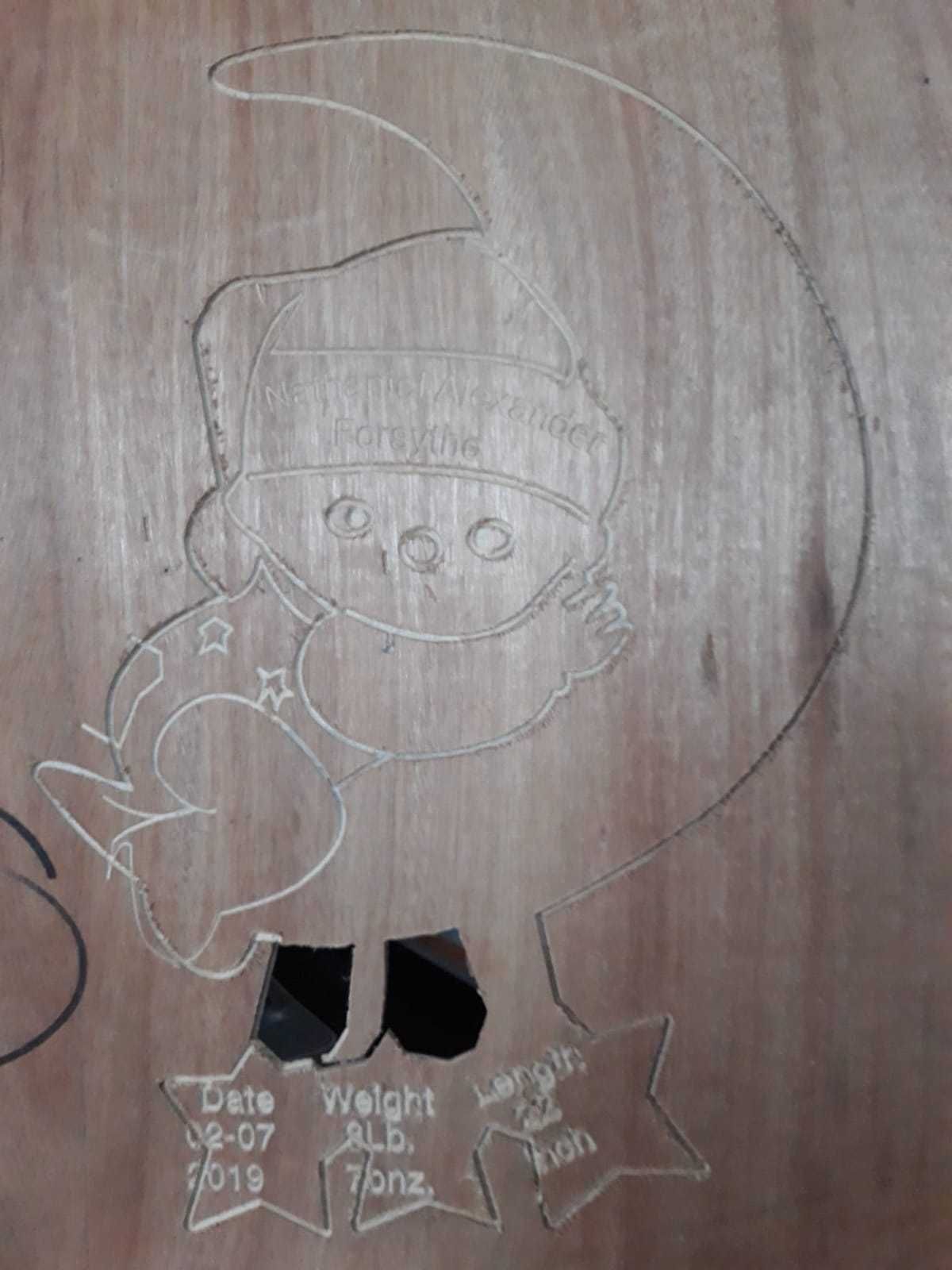

Shift in Project Position

Your project may appear to have shifted to the left, right, up or down

Z-Axis Cutting Too Deep

The Z-Axis is cutting deeper than instructed

Small Lips or Ridges

Noticible ridges around the outline of vectors

Deep Cut Directly Across Project

Related to the Z-Axis, if too low during rapid transits it may leave a gauge across your project

Not Cutting All the Way Through

Depth of cuts not even close to what was instructed

Project Running out of Bounds

Running into limit switches or out of the bounds of your project

Why Am I Losing Steps?

When we experience losing steps, especially for the first time, our minds tend to take a trip down panic lane as they spin with the "whys" and "what ifs". When we break it down, there are really only two main reasons why our machines lose steps ...

Electromagnetic Interference (EMI)

Rare in comparison, but can be even more frustrating. This can be the silent killer as you can not see and hear this like you can when there is a mechanical impediment. This can occur when a machine is 100% free to travel with no mechanical impediments and still appears to lose steps. One of the major signs of this is the randomness of occurances. Any machine controller, such as the UC100 on a STEPCRAFT machine, can be susceptible to EMI from power sources such as power supplies and shop vacuums.

Mechanical Impediment

By far the most common reason for losing steps. This occurs when something (which we will discuss below) physically stops or prevents the axis from moving forward. The subcatagories for this can be vast, but just remember the reason you are losing steps is because the axis can not travel without impediment. Factors that contribute to mechanical impediment can include alignment, dirt and grime, grease, obstructions and feeds and speeds.

How Do I Fix It?

The Only Part You (Probably) Care About

EMI Solutions

Stay Away From the UC100

The UC100 is the grey dongle that plugs into the back of your Stepcraft and runs to your computer VIA USB. This is what interprets and runs the G-Code on your machine and is vulnerable to to EMI. Make sure anything that is electrically charged is as far away from the UC100 as possible (usually 5-10 feet is safe). The major things to consider include power supplies, shop vacs, dust collection systems, and anything else that can throw off static electricity.

Use That Green Cable

Every Stepcraft machine comes with a green grounding cable that can be attached anywhere on the machine, but normally goes on one of the two screws holding the bottom plate on. Make sure your machine is grounded using this cable that plugs into the wall or your power strip. This can help the buildup of static electricity and discharge

Consider Using Ferrites

Ferrites are non-conductive insulators that help to prevent electrical noise from entering equiptment. In this case, these are the "beads" you see on laptop and other electrical cables. Available from Stepcraft or online, these low cost snap on devices can be applied to the USB cord going from the UC100 to your computer and can help prevent stubborn EMI issues.

Mechanical Solutions

100% Jog Speed, 100% Travel

The very first thing to check after losing steps would be your machines mechanical alignment. The goal is to jog your machine at 100% jog speed the full length of each axis. Even if your machine was working perfectly, you may find it binds up towards the ends and needs readjustment. The following videos will walk you through the adjustment process.

Y-Axis Alignment - https://youtu.be/KDuogPSI5tw

Z-Axis Alignment - https://youtu.be/kUG12Z-Lndo

Clean and Re-Grease the Axis

Regular cleaning should be done every 20 hours or so, depending on the material and dust colletion system you are using. If you notice the machine binding in the same spot, this may be a hint that it is time to clean each axis and apply a small amount of re-grease. The following maintenance video will walk you through this process.

Maintenance - https://youtu.be/IIYcZ9M20nU

Check Your Feeds and Speeds

If you are trying to cut too fast (feed rate), too deep (pass depth) or too slow (Speed/RPM's) you may be pushing the machine past its physical limit. Every material has its optimal settings and the more the work with it the more you will have an idea of where you settings should be. A good rule of thumb for most woods is pass depth should be half the diameter of the bit. You can also try using tools such as the G-Wizard Feeds and Speeds calculator (https://www.stepcraft.us/shop/product/45745-g-code-wizard-feeds-speeds-calculator-1-year-subscription-podcast-special-202278?category=31)

When All Else Fails ...

DON'T PANIC

When you purchased your STEPCRAFT machine, you also received a lifetime membership to the best support community in the business! Feel free to reach out to other owners VIA the STEPCRAFT Crafters club on Facebook, give us a call at (203) 556 -1856 or email us at support@stepcraft.us. Our team here at STEPCRAFT has experienced it all and are more than happy to help you through the frustration of losing steps.

My Machine Has Lost It's Mind! The Science Behind Losing Steps and How to Get Back to Work Quickly!