Q.404 CNC System

Starting at: $10,999

The STEPCRAFT Q.404 CNC System offers the ability to process large 4x4 foot materials with an accuracy of +-0.001" and at speeds of up to 475 in/min. The Q.404 also boasts the smallest footprint out of any 4x4 foot CNC in its class, thus saving you valuable floor space in your shop. Every Q.404 is hand built at our facility in Torrington, CT to meet your exact needs.

Every customer has unique needs and requirements for their CNC system. Because of this, it is best to talk to one of our Technical Sales Associates to review your application requirements in order for us to provide you with the exact solution you need. You can reach our sales team at (203)556-1856 or click the "Request Quote" button below.

Additionally, STEPCRAFT offers many optional accessories and add-ons to increase the functionality of your CNC system . Our representative can help guide you through the available options and greatly simplify the buying process.

Please click the button below to request a quotation on a STEPCRAFT Q.404 CNC System.

The Finest In German Engineering

The STEPCRAFT Q-Series sets new standards in the world of computer-aided CNC production systems. The powerful CNC system offers optimal precision and extreme reliability in the manufacturing and processing of high quality work-pieces with a modern design. Thanks to innovative solutions and incorporating the latest in CNC design technology, the Q-Series machines are designed to meet the demanding needs of even the most critical of industrial, woodworking, furniture making and sign making applications. Below we detail the main highlights of the Q-Series CNC systems and many of the options that are available to allow us to build your Q-Series machine to meet your exact needs.

Reinforced Machine Frame

Rigidity and uniformity are critical on a large format CNC system. The Q-Series machines utilize engineered aluminum frame components that are all custom extruded using our own proprietary-designed dies. You will not find any "off-the-shelf" structural components on a Q-Series CNC. Every detail has been considered to give you the strongest engineered frame possible with superior tolerances.

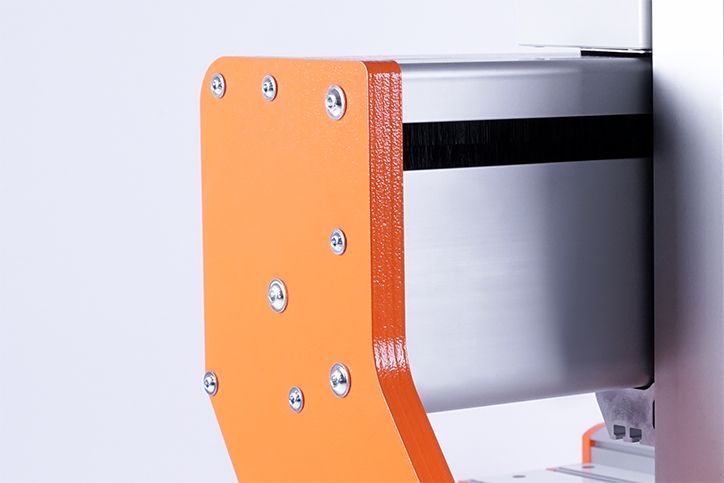

Laminated Steel Gantry Supports

The gantry uprights on the Q-Series machines are made from 5-layer welded laminated steel, which have been engineered to provide superior strength while allowing for all wiring to be protected and hidden from view. Laminated designs are stronger, stiffer, and can handle much higher loads than solid counterparts. A durable powder-coated paint is applied for a superior finish.

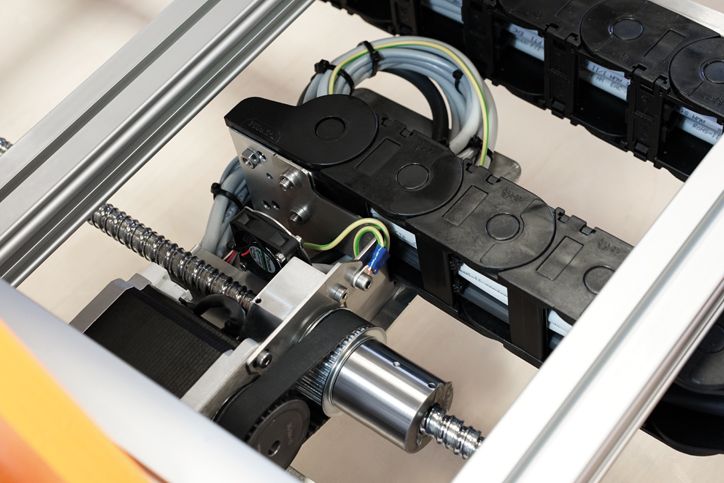

Accurate, Responsive Drive System

The Q-Series systems utilize precision ball screws on all axes. The Y-axis of the Q.404 has an encoded stepper drive system on both sides of the gantry. These drives operate by spinning the ball screw nut rather than the entire ball screw. This same design is also found in the X-axis with a single drive system. This allows all of the motor's power and resolution to be utilized in the axis's motion rather than wasting power spinning the mass of the ball screw. The result is ultra-fast acceleration and deceleration with incredible accuracy.

Hiwin Zero Backlash Ball Screws

When you are looking for the most accurate CNC drive system possible, then ball-screw drives are the only way to go. They do not have the backlash or maintenance issues that you find with rack and pinion systems. Hiwin is a world leader in the engineering and manufacturing of precision ball screws and every Q-Series CNC uses them on all axes, giving you the best possible accuracy with repeatability of <0.0006"

STEPCRAFT All-Steel Motion System®

The STEPCRAFT Q-Series CNC systems feature a proprietary STEPCRAFT All-Steel Motion System®. This linear guide system is uses 20mm hardened steel rails that are precision ground for superior accuracy. The each steel roller contains two precision HSK bearings with a total of 8 per side on the Y axes and 8 on the X and Z. The end result is a ultra smooth, low maintenance motion system system designed to outperform traditional linear guides commonly found on other CNC systems.

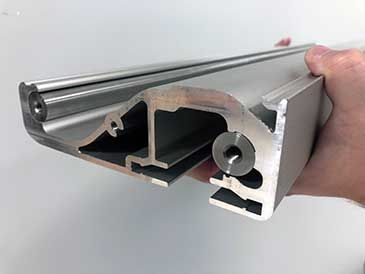

Engineered Aluminum Extrusions

Don't think that just because the major frame components are made from aluminum that you are sacrificing strength and rigidity, because you would be wrong. Frame profiles like the X axis (shown above) are highly engineered to match the strength of steel-frame competitors. Finite element analysis software was used to calculate stress loads and ensure maximum performance from every frame component. There is a reason why the worlds highest performance supercars use aluminum in their engine and drive systems - lighter, stronger, maximum performance.

Three Q-Series Machine Sizes Available

There are three sizes of the Q-Series available to our customers to ensure that no matter what your application, we have you covered. The Q.204 is a 2x4 foot machine that comes with our without a steel stand so it can be installed on a work bench that you might already have. The Q.404 and Q.408 machines are built on a structural steel frame. All three machines ship fully custom built to the individual customer's specifications and are fully tested prior to leaving our facility.

Concealed Drive Systems

Each axis was designed to be completely concealed using brushes or seal profiles that are integrated into the frame extrusions. These brushes keep 99% of dust and debris out of the critical drive components which yields long, low-maintenance, production cycles. The guide rails, ball screws and other components will always run at their peak and not be susceptible to common maintenance issues found on systems with exposed drive systems. Your uptime is our number one goal

Redundant Protection On All Axes

The Q-Series systems all feature not only software limit protection, but each end of every axis has an integrated industrial mechanical limit switch. Typical CNC systems use a homing switch on one side of the axis which leaves no protection against a possible crash. The dual limit switch design of the Q ensures that your machine and drive system are always protected in the event of an error in CAM programming or a major jam such as accidentally hitting a steel clamp. Should an accident happen, your machine is protected!

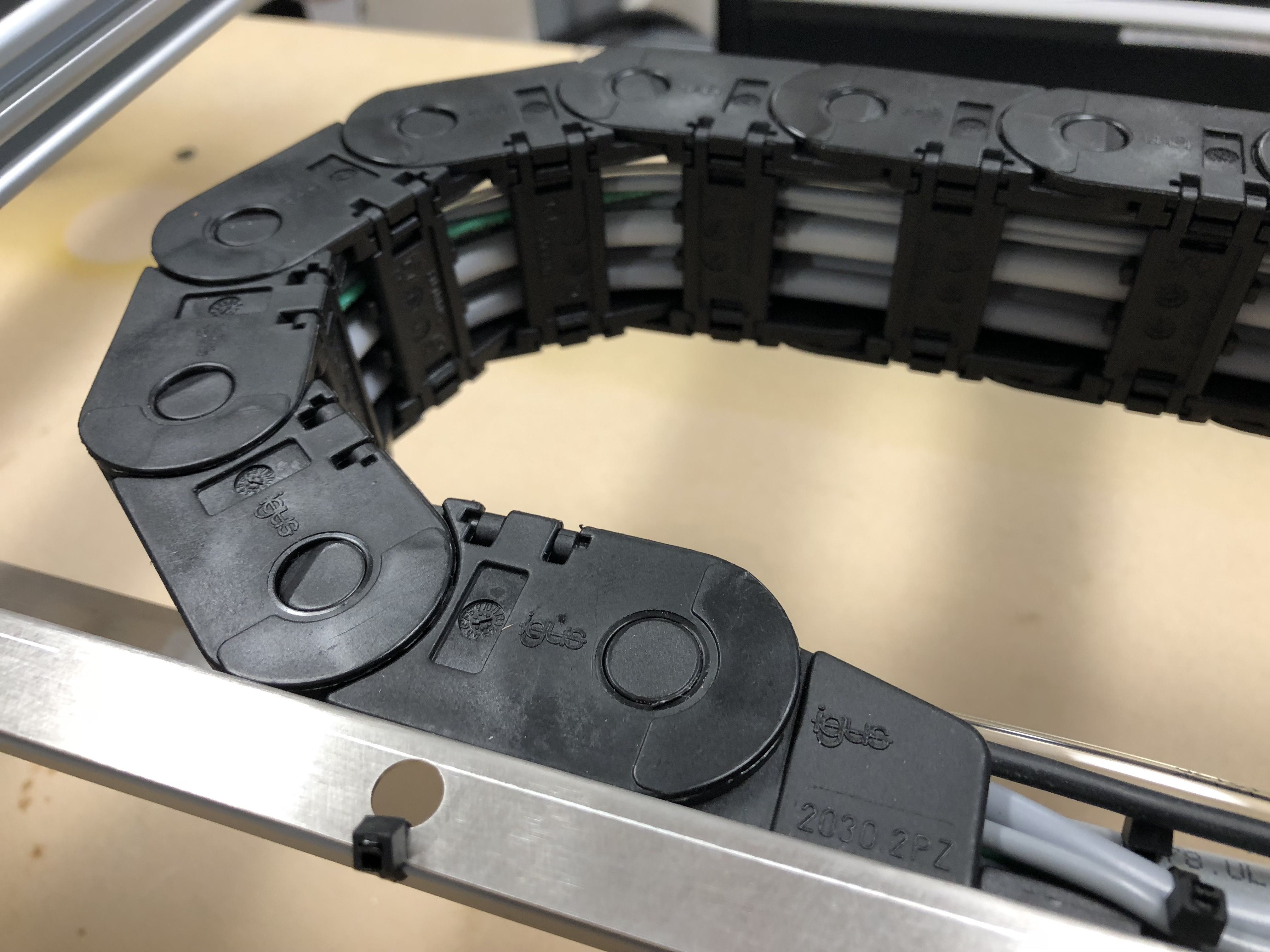

Concealed Cable Routing

The Q-Series CNC systems use the highest quality IGUS cables in all areas of the machine. They have a bend rating of 10 million cycles ensuring a lifetime of reliability, giving every customer industrial-grade production cycles out of every machine. All cables are concealed and routed throughout the machine in IGUS energy chains protecting them from the rigors of a CNC production environment. In fact, 95% of all wiring on the Q-Series systems are concealed from view, providing a clean look with no chance of any wiring getting in the way of your productivity.

Powerful Sanyo-Denki Motors

Powerful Sanyo-Denki NEMA 24, 4 amp, high resolution stepper motors are used on all axes. Thanks to the responsive drive system (shown above on X and Y) where the motor is controlling the ball screw nut rather than the entire ball screw, all of the motors energy and resolution can be directed to each control axis. The result is accuracy and control comparable to that found in servo-driven systems costing 3-4 times as much. You sacrifice nothing with a STEPCRAFT Q-Series CNC system.

Easy Serviceability

It is easy to service the gantry system on the Q-Series machines by simply removing covers to access all control systems. The covers complete the Concealed Drive System keeping virtually all dust and debris from getting into the drive systems which vastly lengthens time between maintenance and keeps your Q-Series CNC producing as much as you need it.

Integrated LED Lighting

Good lighting on a CNC system is essential, specifically when setting up your jobs or inspecting jobs as they are being produced. Every Q-Series CNC system has an integrated LED lighting strip on the bottom of the X axis with enough brightness to illuminate your entire work area.

WATCH THE VIDEOS TO LEARN MORE

Intelligent Mix Of Materials

One of the great advantages of the Q-Series lies in the smart combination of heavy-duty STEPCRAFT custom aluminum extrusions and steel components ensuring rigidity, extremely low vibration while maintaining lower weight which allows for faster axis movement and for more precise machining applications.

CE Compliant - The Safest CNC

STEPCRAFT went above and beyond when it comes to the level of safety features that have been integrated into the Q-Series CNC systems. Ensuring that all pinch points have been eliminated coupled with X axis safety bumpers protect the operators fingers and limbs as the machine is in motion. These features and more are part of our stringent CE certification and are appreciated by Schools, Clubs and Maker spaces where they can take solace knowing that their operators are using a certified, safe CNC system.

Clean, Uncluttered Euro Design

As we mentioned above that great efforts were made in the design of the Q-Series CNC systems to conceal wiring, drive components and guide systems to ensure long times between maintenance intervals. This also holds true for the external profiles of the machine frame. Custom extruded aluminum profiles completely encapsulate the exterior of the machine keeping everything clean and uncluttered so you can focus on using the machine rather than cleaning and maintenance of it.

Table Flatness Is Critical

Each Q-Series system utilizes up to 10 custom aluminum extruded cross supports which interlock into the side frame panels on the machine. This keyed design ensures that the entire table area is flat in relation to the main frame. This design ensures a flatter work table which yields cleaner, more precise finishes of your workpieces, especially when multiple cutting tools are being used in a single job. This uniformity gives you exceptional surface finishes to all your jobs.

Structural Steel Frame

The Q.404 and Q.408 machines come standard with a 1/8" wall, 3" square tube structural steel frame (optional on the Q.204). Each frame is precision welded to exacting tolerances and then a durable paint is applied designed to stand up to the harshest environments. The solid steel frame is the foundation that the machine is built upon and since the Q-Series CNC systems are designed for high production use and for processing of a wide variety of materials including non-ferrous metals like aluminum, it is imperative that they are solid from the ground up.

OneTech®

Our OneTech quality philosophy guarantees that each CNC machine has been completely hand-crafted and checked by the designated STEPCRAFT technician. The Q-Series machines are custom-built for each customers requirements and by utilizing a non-assembly line process, we ensure that the utmost in pride and care is taken on every machine that leaves our facility in Torrington, CT. Only after completing a rigorous testing of all functionalities will a system be released and marked with our OneTech quality seal.

Universal Z-Tool Holder

To ensure that your Q.404 system can meet all of your present and future needs, it includes six T-slots in the Z-axis extrusion. This allows you to adjust the spindle height range as well as attach other devices, such as dust collection, mist lubrication and other STEPCRAFT attachments.

Integrated Aluminum T-Slots

Every Q-Series CNC comes standard with a white formica-coated MDF table with integrated aluminum T-slots. This ensures that you have the most flexibility when fixing your workpieces to the machine. An optional all-aluminum T-slot table can be added in place of the standard table and is best for when you plan to use mist cooling for metal machining.

Virtually Unlimited Workpiece Length

The open Y-axis pass-through design of the Q.404 machine table allows you to process longer material lengths using "Tiling" in your CAM program, splitting the job into multiple files that are up to 48" long. This gives you virtually unlimited machine capability with a 4 foot machine.

Metal Cutting Capability

All of the Q-Series CNC systems are designed to handle many materials in a production environment. This includes machining of non-ferrous metals like aluminum, brass and copper. When coupled with a 3hp or greater spindle the Q.404 can achieve very accurate results - with greater performance and precision than many CNC routers on the market.

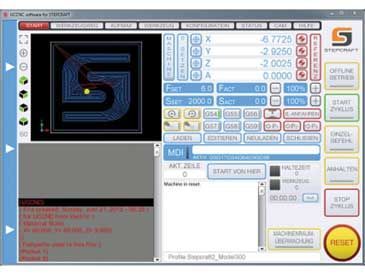

UCCNC Machine Control Software

Every Q-Series CNC system sold in the USA, Canada and Mexico comes with UCCNC machine control software. This powerful software runs G-Code files generated using your favorite CAD/CAM software, such as Vectric V Carve Pro, Autodesk Fusion 360, Solidworks, MasterCam and more. To make the learning process easy, we have a free online video training course on UCCNC available to all customers.

German Engineered - American Built

The STEPCRAFT Q-Series line of CNC systems gives you the best of both worlds - high quality, fine detailed German engineering and American-built by our dedicated team of CNC assembly technicians. Working closely with our German team, we ensure that every CNC system that we ship is perfect and meets all of our critical testing standards.

Q.404 Technical Specifications

| Machine's Footprint (Width, Length, Height) |

63" x 63" x 68" |

| X-Axis Travel | 49.8" (1223 mm) |

| Y-Axis Travel | 49.8" (1223 mm) |

| Z-Axis Travel | 5.7" (145 mm) |

| Gantry Clearance (Z) | 7.67" (195mm) |

| Table Work Area (X, Y) | 55.1" x 58.1" (1400 x 1476 mm) |

| Max Feed Rate | 475 in/min (200 mm/sec) |

| Drive Unit | Precision Ball Screws on X, Y, and Z |

| Linear Drive | All-Steel-Motion System® |

| Positional Accuracy/Repeatability |

+/- 0.00019" (+/- 0.005 mm) |

| Weight |

925 lbs. |

| Power Requirements |

110V, 50-60 Hz, 10A, Single Phase (for base machine) a second 110V, 50-60 Hz, 15A, Single Phase outlet is required for the MM-1000 or 3.25HP router. Note: If using the HFS-2200 or ATC-2200 spindles you will require 220V Single Phase 30A for the entire system. |

| Interface |

USB 2.0 / Ethernet (Optional) |

| Computer Requirements |

PC with 1Ghz Processor (Laptop, Desktop or All-in-One), USB 2.0 interface, Windows 7 or higher (32/64 bit) OR MAC OS X 10.3.9 or higher with Windows emulation (Parallels or BootCamp) |

|

|

|

|

|

|

Q-Series Options

One of the best features of the STEPCRAFT Q-Series CNC Systems is the ability to have the machines custom-configured to meet your exacting needs. With multiple spindle, table, and accessory choices, your Q-Series CNC can be the ultimate in sign making, cabinet making, foam cutting, leather cutting, aluminum machining and much more. Below are some of the options that are available. For more information, please request a proposal or contact one of our knowledgable sales consultants today.

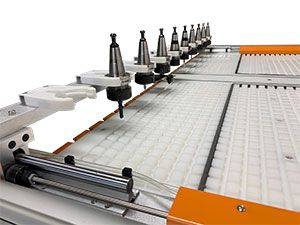

ATC-2200 2.2KW Automatic Tool Changer Spindle

For the ultimate in productivity, fully-automate your Q-Series CNC system with the ATC-2200 spindle. This passively-cooled spindle (not air, not water) is one the quietest and coolest running CNC spindles around, producing over 3hp of raw machining power. The spindle uses ISO30 tool holders with ER32 collets capable of up to 3/4" shanks. You can custom configure your CNC with tool racks in almost any position, holding up to 10 tools on the machine. (Talk to a sales consultant about these options). Our software makes configuring and setting up tools fast and easy.

HFS-2200 2.2kW Air-Cooled Spindle

When you are looking for the raw power and accuracy of a CNC spindle, but you do not need the automation from an automatic tool changer, the HFS-2200 can be the solution. The HFS-2200 is a 3hp air-cooled spindle that supports up to 1/2" shank tooling using ER20 collets. The speed control is completely driven electronically from the Siemens VFD (Variable Frequency Drive).

3 1/4 HP Router

Sometimes you do not have the budget of a traditional spindle but you still need a lot of milling power. This is where the 3.25 HP Variable Speed router is a solid solution. This router is very popular in the woodworking and carpentry community and replacements parts and units can be easily obtained online and from woodworking specialty stores. The router has an RPM knob that allows infinite adjustment of RPM depending on your job and tooling. Also when using a 3.25 HP router with your Q-Series CNC, the power requirements are reduced from 220V single phase to a standard 15 amp 110V house circuit.

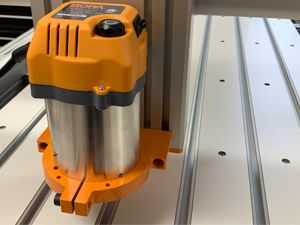

1kW MM-1000 Air Cooled Spindle

Some applications require the larger format size of the Q-Series machines, but do not require the power from a traditional high-power spindle. An example might be foam cutting, PC board work, or other thin, easy-to-cut materials. The MM-1000 spindle is a 1kW unit producing about 1.4hp. It has a variable speed control dial on the top of the unit to set your RPMs. You are limited to 1/4" max shank size but if your application does not demand large bits or aggressive cutting then this spindle is an affordable and highly accurate solution.

4 Zone Vacuum Table

Processing panel material for signs, cabinet making, or furniture has never been easier. STEPCRAFT's 4 zone vacuum table for the Q.404 CNC system gives you 4independent zones that you can control depending on your work material size, or simply turn on all zones for 4x4 foot sheet materials. The system has 6 integrated T-tracks for applications where you do not need vacuum. The vacuum table is unique because with the use of 3/8" foam rubber cord, you are able to custom configure the layout of the vacuum area around each vacuum port. This is perfect for making custom fixtures for production work.

Full Aluminum T-Slot Table

When you need to machine a lot of non-ferrous metals such as aluminum, brass and copper, you might find it necessary to use a mist cooling system to lubricate and cool your cutting tools as you engage the material. For these applications, you need a very heavy, rigid T-slot system that is impervious to liquids. The aluminum T-slot table also adds double the number of T-tracks for M8 T-nuts accessible from the front and M6 T-nuts accessible from the rear of the machine.

Standard MDF/Aluminum T-Track Table

The standard bed option that comes on every Q-Series CNC system is comprised of Formica coated dense MDF boards with full-length M8 T-nut aluminum T-tracks in between. This bed system give you a lot of flexibility for countless projects and clamping options. You can easily utilize a variety of industry clamping systems as well as having the capability to setup various fixtures at different locations on the table for repetitive production work.

Pneumatic Sliding Tool Rack for ATC

In many shops, floor space is at a premium. STEPCRAFT has designed the Q-Series CNC systems to have the smallest footprint possible, up to 25% shorter than competitive machines. The fact is that the space at the rear of the machine is a "dead zone" and it not usually included in the cutting area. This is often where you would find the tool rack for the automatic tool changer. To minimize this required "dead zone" space, an optional Pneumatic Sliding Tool Rack can be used to move the tool rack out of the cutting area when not in use and then it slides forward to engage the tools during a tool change. This innovation gives you full ATC capability in the smallest footprint possible.

43mm Accessory Bracket

STEPCRAFT is known as the world leader in multi-function CNC systems. We have over 12 optional tools that can be added to our CNC machines. We wanted to incorporate the same flexibility and multi-function capability to our Q-Series line of machines as well. Since the spindles are heavy and come pre-trammed from the factory, we do not want customers to have to remove them. The 43mm Accessory Bracket quickly attaches to the T-slots in the Z axis and surrounds the spindle giving you easy access to adding a laser, tangential knife, hot wire cutter and more.

Tool Length Sensor

STEPCRAFT's Tool Length Sensor makes it quick and easy to setup your jobs and get perfect Z height registration from tool to tool every time. In addition to locating a job's Z height, the Tool Length Sensor is also used with the Automatic Tool Changer to automatically measure every tools height offset and record the values into the system. NOTE: As of 4-1-29, all Q-Series CNC Systems are now including the Tool Length Sensor at no extra charge

3D Touch Probe

The 3D Touch Probe is probably one of the most versatile products that you can add to a Q-Series CNC system. It gives you the ability to quickly and accurately locate the edges of a part, the center of a part, and to measure parts from edge to edge. Additionally you can use the 3D Touch Probe to digitally level your bed to >0.001", which is critical when doing fine detail work like circuit boards. You can also use the 3D Touch Probe to 3D scan objects and turn them into solid models that you can carve and replicate. When used with the ATC-2200 spindle, you can install it in a ISO30 tool holder and quickly load and unload it from the machine during job setups.

Floating Dust Collection Boot

There is no denying that a CNC router can make a lot of dust and chips quickly. A good dust collection solution is a critical part of keeping a clean work area and keeping airborne particles to a minimum. STEPCRAFT's dust boots are designed to float on the material surface independently from the Z axis motion of the spindle. This ensures that there is always positive engagement between the brush and the material surface which dramatically increases the amount of dust that your vacuum system can collect. There are two versions, a manual one for the HFS-2200 spindle and an automatic dust boot for the ATC-2200 spindle which raises and lowers automatically for tool changes.