Q.408 CNC System

Pre-Launch Price: $29,999

The STEPCRAFT Q.408 CNC System offers the ability to process full 4x8 foot sheet stock with an accuracy of +-0.001" and at speeds of up to 1000 in/min. Every Q.408 is hand built at our facility in Torrington, CT to meet your exact needs.

Every customer has unique needs and requirements for their CNC system. Because of this, it is best to talk to one of our Technical Sales Associates to review your application requirements in order for us to provide you with the exact solution you need. You can reach our sales team at (203)556-1856 or click the "Request Quote" button below.

Additionally, STEPCRAFT offers many optional accessories and add-ons to increase the functionality of your CNC system . Our representative can help guide you through the available options and greatly simplify the buying process.

Please click the button below to request a quotation on a STEPCRAFT Q.408 CNC System.

THE NEW STEPCRAFT Q-SERIES - AVAILABLE FOR PRE-ORDER NOW

Shipping June 2024

When STEPCRAFT introduced the Q-Series over 5 years ago, it took the world by storm

Technical Specifications of the STEPCRAFT Q.408 CNC System

| Machine's Footprint (Width, Length, Height) | 73" x 118" x 68" |

| X-Travel | 49.8" (1223 mm) |

| Y-Travel | 96.5" (2451 mm) |

| Z-Travel | 5.7" (145 mm) |

| Gantry Clearance (Z) |

7.67" (195 mm) |

| Table Work Area (X, Y) |

55.1" x 106.3" (1400 x 2700 mm) |

| Max Feed Rate | 1200 in/min (200 mm/sec) |

| Drive Unit | Precision Ball Screws on X, Y, and Z |

| Linear Drive | All-Steel-Motion System® |

| Positional Accuracy/Repeatability |

+/- 0.00019" (+/- 0.005 mm) |

| Weight |

1275 lbs. |

| Power Requirements |

110V, 50-60 Hz, 10A, Single Phase (for base machine) a second 110V, 50-60 Hz, 15A, Single Phase outlet is required for the MM-1000 or 3.25HP router. Note: If using the HFS-2200 or ATC-2200 spindles you will require 220V Single Phase 30A for the entire system. |

| Interface |

USB 2.0 / Ethernet (optional) |

| Computer Requirements |

PC with 1Ghz Processor (Laptop, Desktop or All-in-One), USB 2.0 interface, Windows 7 or higher (32/64 bit) OR MAC OS X 10.3.9 or higher with Windows emulation (Parallels or BootCamp) |

|

|

|

|

|

|

Q-Series Options

One of the best features of the STEPCRAFT Q-Series CNC Systems is the ability to have the machines custom-configured to meet your exacting needs. With multiple spindle, table, and accessory choices, your Q-Series CNC can be the ultimate in sign making, cabinet making, foam cutting, leather cutting, aluminum machining and much more. Below are some of the options that are available. For more information, please request a proposal or contact one of our knowledgable sales consultants today.

ATC-2200 2.2KW Automatic Tool Changer Spindle

For the ultimate in productivity, fully-automate your Q-Series CNC system with the ATC-2200 spindle. This passively-cooled spindle (not air, not water) is one the quietest running CNC spindles with lowest standard operating temperature around, producing over 3hp of raw machining power. The spindle uses ISO30 tool holders with ER32 collets capable of up to 3/4" shanks. You can custom configure your CNC with tool racks in almost any position, holding up to 10 tools on the machine. (Talk to a sales consultant about these options). Our software makes configuring and setting up tools fast and easy.

HFS-2200 2.2kW Air-Cooled Spindle

When you are looking for the raw power and accuracy of a CNC spindle, but you do not need the automation from an automatic tool changer, the HFS-2200 can be the solution. The HFS-2200 is a 3hp air-cooled spindle that supports up to 1/2" shank tooling using ER20 collets. The speed control is completely driven electronically from the Hitachi VFD (Variable Frequency Drive).

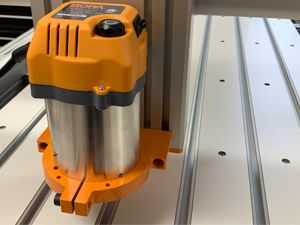

3 1/4 HP Router

Sometimes you do not have the budget of a traditional spindle but you still need a lot of milling power. This is where the 3.25 HP Variable Speed router is a solid solution. This router is very popular in the woodworking and carpentry community and replacements parts and units can be easily obtained online and from woodworking specialty stores. The router has an RPM knob that allows infinite adjustment of RPM depending on your job and tooling. Also when using a 3.25 HP router with your Q-Series CNC, the power requirements are reduced from 220V single phase to a standard 15 amp 110V house circuit.

1kW MM-1000 Air Cooled Spindle

Some applications require the larger format size of the Q-Series machines, but do not require the power from a traditional high-power spindle. An example might be foam cutting, PC board work, or other thin, easy-to-cut materials. The MM-1000 spindle is a 1kW unit producing about 1.4hp. It has a variable speed control dial on the top of the unit to set your RPMs. You are limited to 1/4" max shank size but if your application does not demand large bits or aggressive cutting then this spindle is an affordable and highly accurate solution.

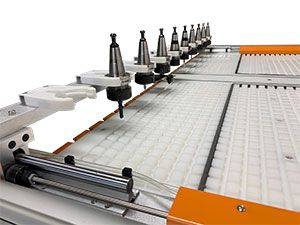

6 Zone Vacuum Table

Processing panel material for signs, cabinet making, or furniture has never been easier. STEPCRAFT's 6 zone vacuum table for the Q.408 CNC system gives you 6 independent zones that you can control depending on your work material size, or simply turn on all zones for 4x8 foot sheet materials. The system has 4 integrated T-tracks for applications where you do not need vacuum. The vacuum table is unique because with the use of 3/8" foam rubber cord, you are able to custom configure the layout of the vacuum area around each vacuum port. This is perfect for making custom fixtures for production work.

Standard MDF/Aluminum T-Track Table

The standard bed option that comes on every Q-Series CNC system is comprised of Formica coated dense MDF boards with full-length M8 T-nut aluminum T-tracks in between. This bed system give you a lot of flexibility for countless projects and clamping options. You can easily utilize a variety of industry clamping systems as well as having the capability to setup various fixtures at different locations on the table for repetitive production work.

Pneumatic Sliding Tool Rack for ATC

In many shops, floor space is at a premium. STEPCRAFT has designed the Q-Series CNC systems to have the smallest footprint possible, up to 25% shorter than competitive machines. The fact is that the space at the rear of the machine is a "dead zone" and it not usually included in the cutting area. This is often where you would find the tool rack for the automatic tool changer. To minimize this required "dead zone" space, an optional Pneumatic Sliding Tool Rack can be used to move the tool rack out of the cutting area when not in use and then it slides forward to engage the tools during a tool change. This innovation gives you full ATC capability in the smallest footprint possible.

43mm Accessory Bracket

STEPCRAFT is known as the world leader in multi-function CNC systems. We have over 12 optional tools that can be added to our CNC machines. We wanted to incorporate the same flexibility and multi-function capability to our Q-Series line of machines as well. Since the spindles are heavy and come pre-trammed from the factory, we do not want customers to have to remove them. The 43mm Accessory Bracket quickly attaches to the T-slots in the Z axis and surrounds the spindle giving you easy access to adding a laser, tangential knife, hot wire cutter and more.

Tool Length Sensor

STEPCRAFT's Tool Length Sensor makes it quick and easy to setup your jobs and get perfect Z height registration from tool to tool every time. In addition to locating a job's Z height, the Tool Length Sensor is also used with the Automatic Tool Changer to automatically measure every tools height offset and record the values into the system. NOTE: As of 2020, all Q-Series CNC Systems are now including the Tool Length Sensor at no extra charge

3D Touch Probe

The 3D Touch Probe is probably one of the most versatile products that you can add to a Q-Series CNC system. It gives you the ability to quickly and accurately locate the edges of a part, the center of a part, and to measure parts from edge to edge. Additionally you can use the 3D Touch Probe to digitally level your bed to >0.001", which is critical when doing fine detail work like circuit boards. You can also use the 3D Touch Probe to 3D scan objects and turn them into solid models that you can carve and replicate. When used with the ATC-2200 spindle, you can install it in a ISO30 tool holder and quickly load and unload it from the machine during job setups.

Floating Dust Collection Boot

There is no denying that a CNC router can make a lot of dust and chips quickly. A good dust collection solution is a critical part of keeping a clean work area and keeping airborne particles to a minimum. STEPCRAFT's dust boots are designed to float on the material surface independently from the Z axis motion of the spindle. This ensures that there is always positive engagement between the brush and the material surface which dramatically increases the amount of dust that your vacuum system can collect. There are two versions, a manual one for the HFS-2200 spindle and an automatic dust boot for the ATC-2200 spindle which raises and lowers automatically for tool changes.