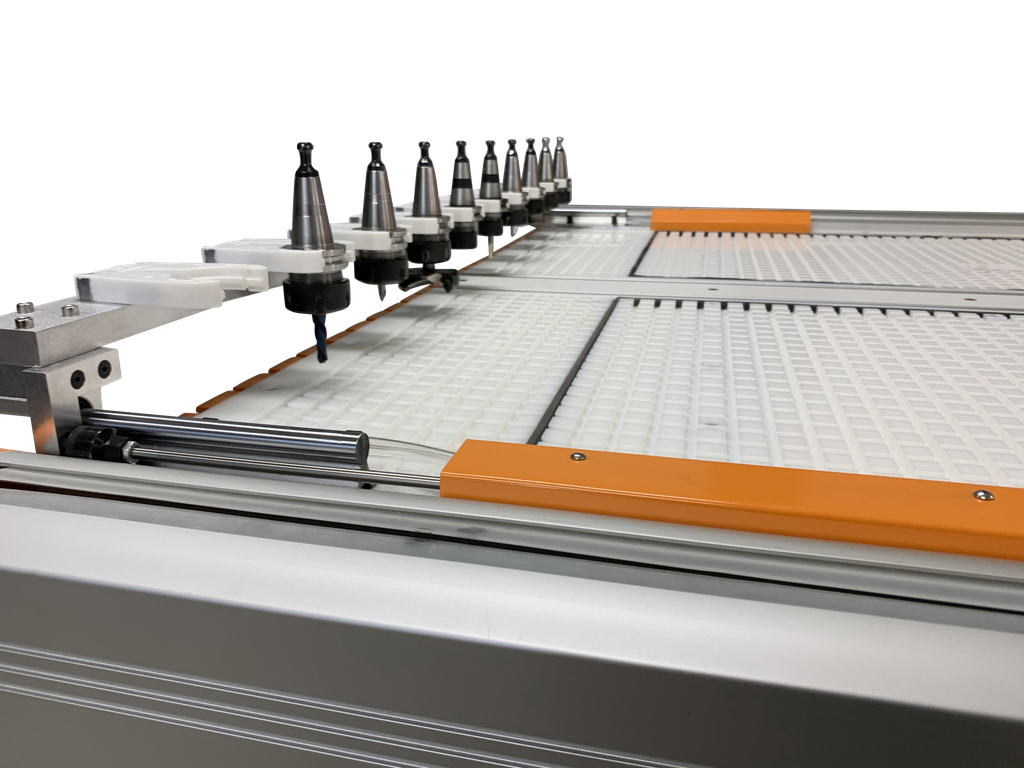

Automatic Sliding Tool Rack (Q.404 and Q.408)

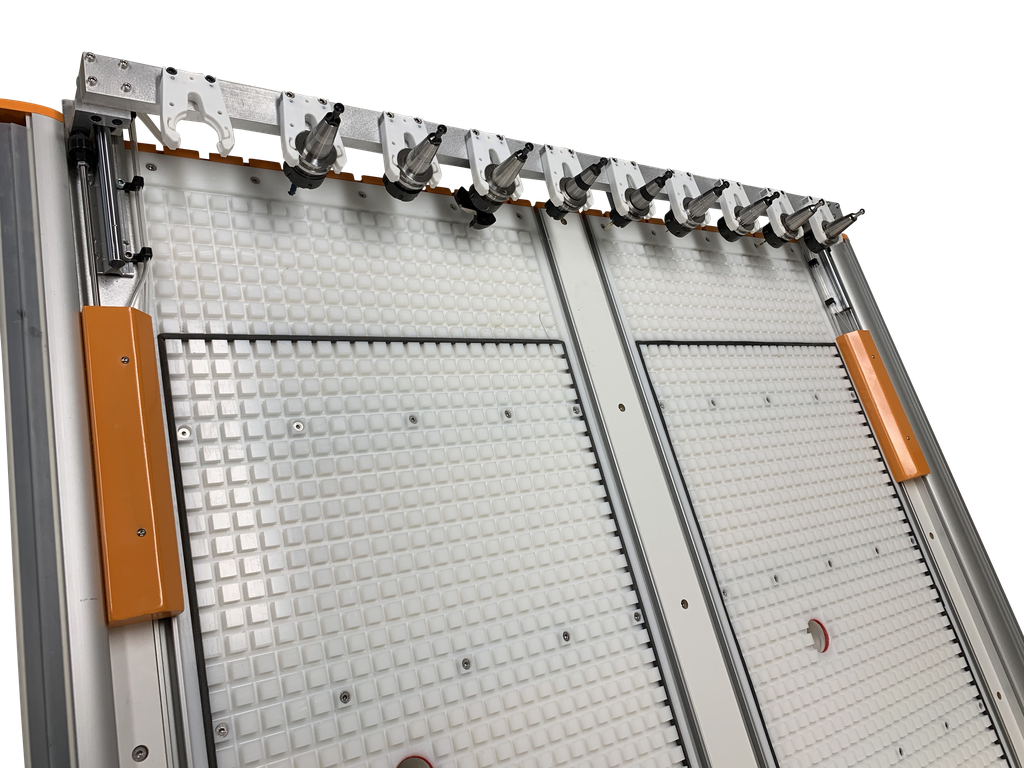

Upgrade from standard, fixed, 4pc rear tool rack

Providing More Usable Y-Axis On The Q.404 and Q.408 CNC Systems

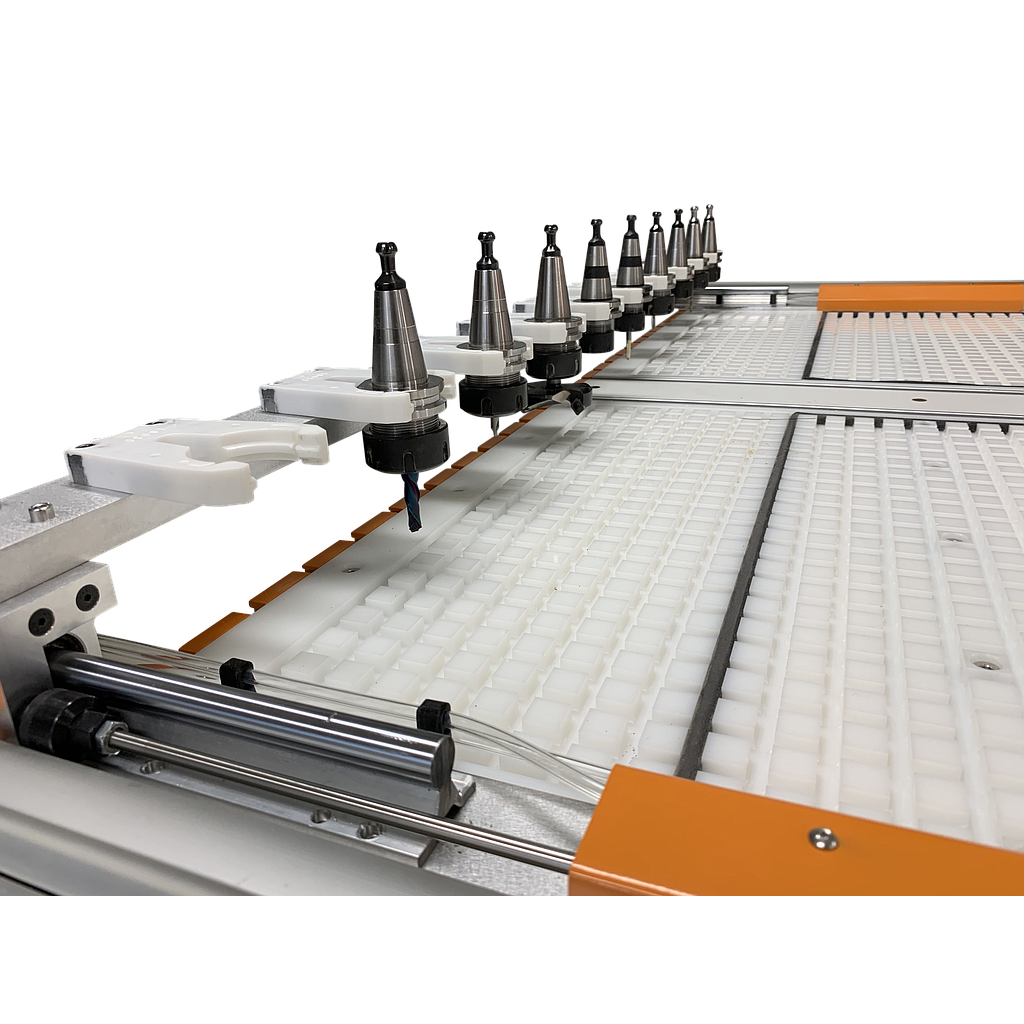

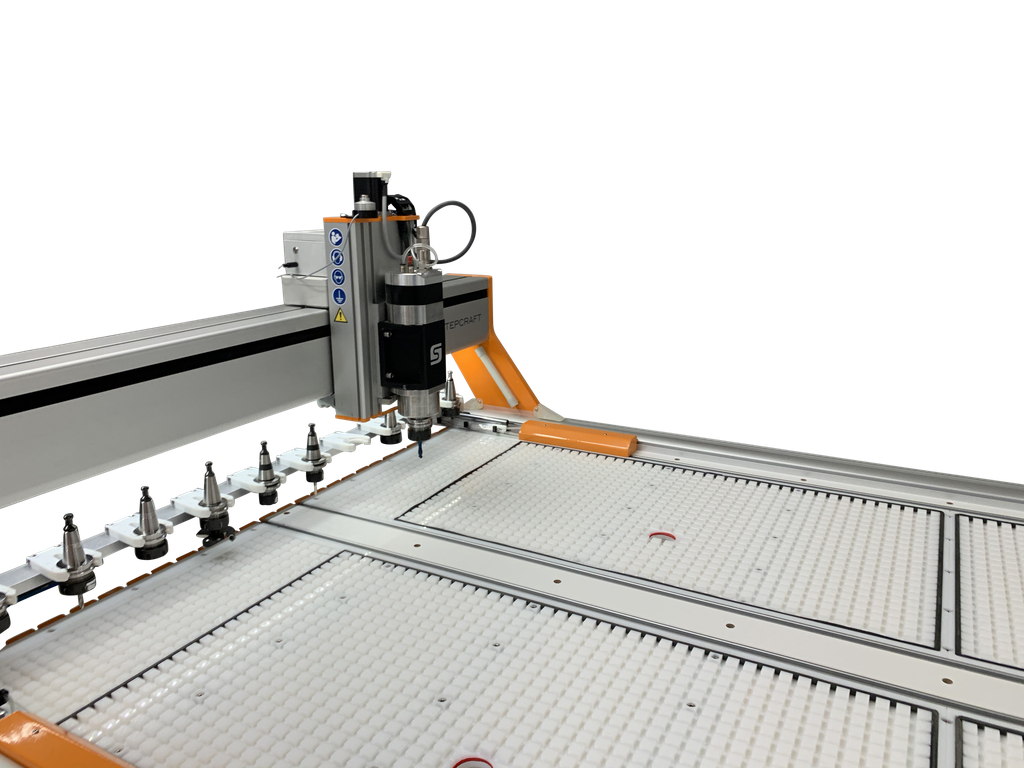

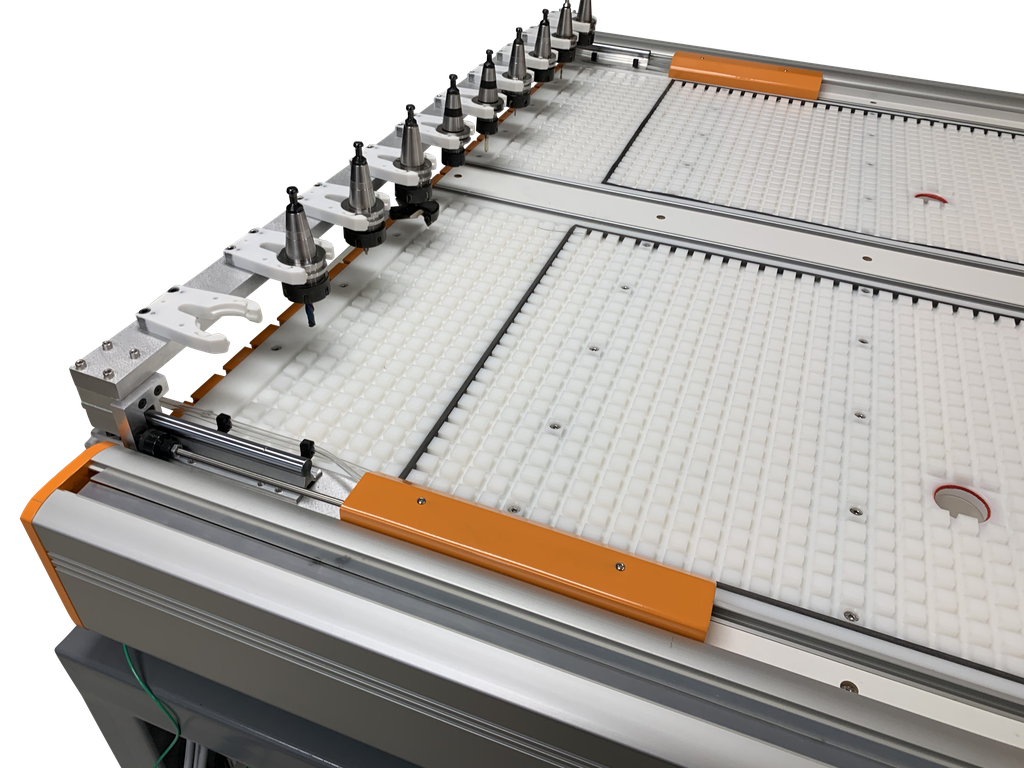

When you buy a large format CNC system, you are looking to process the largest possible material you can. The new Pneumatic Sliding Tool Rack, gives you 7 more inches of usable space on the Y-Axis of the CNC when using the Automatic Tool Changer (ATC-2200 Spindle). The tool rack will support up to 10 ISO30 Tool Holders to give you maximum flexibility for automating your CNC projects.

The STEPCRAFT Q.408 CNC System has the smallest footprint out of any 4 x 8 foot CNC on the market. We know that space in many shops can be a premium and square footage is not cheap. It's innovations like Pneumatic Sliding Tool Rack, that make STEPCRAFT a world leader in CNC technology and solutions.

How It Works

When it is time to make a tool change, the tool rack will pneumatically slide forward to deliver the tool holder to the spindle and then retract out of the way after the spindle has to tool. When returning a tool, the tool rack will slide forward to engage the tool holder in the spindle allowing it to be released by spindle and move to pick up the next tool and then it will retract again to the rear of the machine.

Specifications

Number of Tools: 10

Tool Holder Type: ISO30 (ER32 or ER25)

Air Pressure Required: 110 PSI (taps into the air for the ATC-2200 Spindle)

Length of Travel: 7"

Retraction/Extension Time: 1.2 seconds