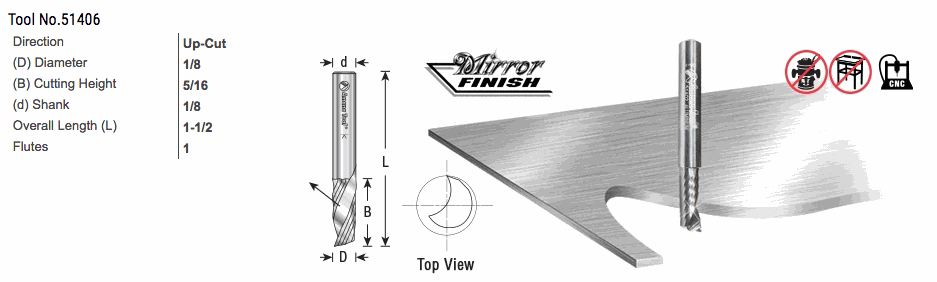

Amana Tool 51406 Solid Carbide CNC Spiral 'O' Flute, Aluminum Cutting 1/8 Dia x 5/16 x 1/8 Shank Up-Cut

Amana Tool 51406 O Flute Aluminum Cutting 1/8" Up-Cut

To be used only on CNC machines and routers with automatic feeding.

Using the highest quality sub-micrograin carbide these bits have a special proprietary edge processing system featuring a super high polished cutting edge with a unique “mirror finish” resulting in clean cuts, less chance for chip re-welding, a superior surface finish and a longer tool life. Right hand helix right hand cut.

Specifically designed for a variety CNC machining applications excellent for cutting:

- ALPOLIC® Copper Composite Material (CCM)

- Alucobond®

- Aluminum

- Aluminum 6061

- Aluminum Alloys

- Aluminum Composite Materials (ACM)

- Aluminum Composite Panel (ACP)*

- Alupanel®

- Brass

- Copper

- Dibond®

- Durabond**

- e-panel™

- Etalbond®

- Gold

- Non-Ferrous Metals

- Plastic

- Silver

- Solid Surface

- Titanium Composite Material (TCM)

- Wood

Ideal for industrial applications our spiral ‘O’ flute router bits are manufactured using innovative techniques and materials that yield superior results with each cut and help make aluminum projects less labor-intensive.

Benefits of Mirror-Finish:

- Razor sharp cutting edge

- Effortless chip removal

- Helps prevent chip re-welding

- Extends tool life

- Exceptional cut quality

- Dissipates heat well and prevents melting