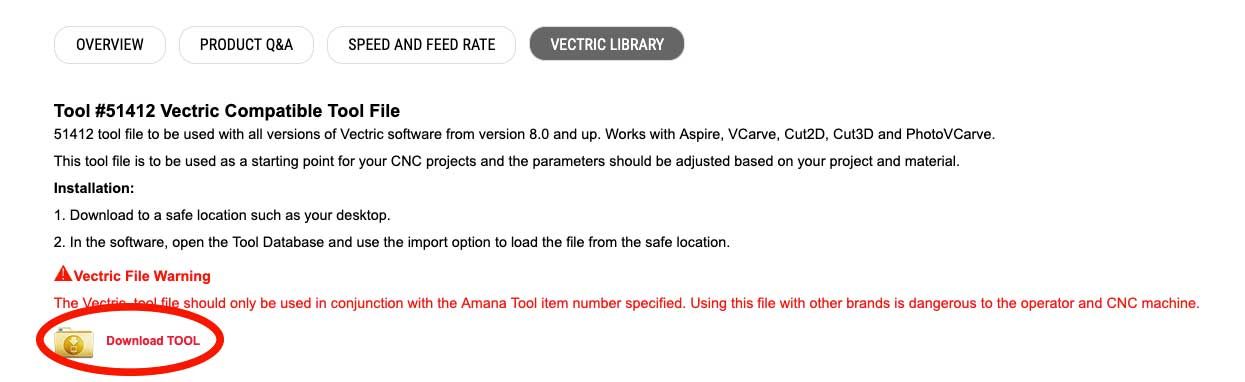

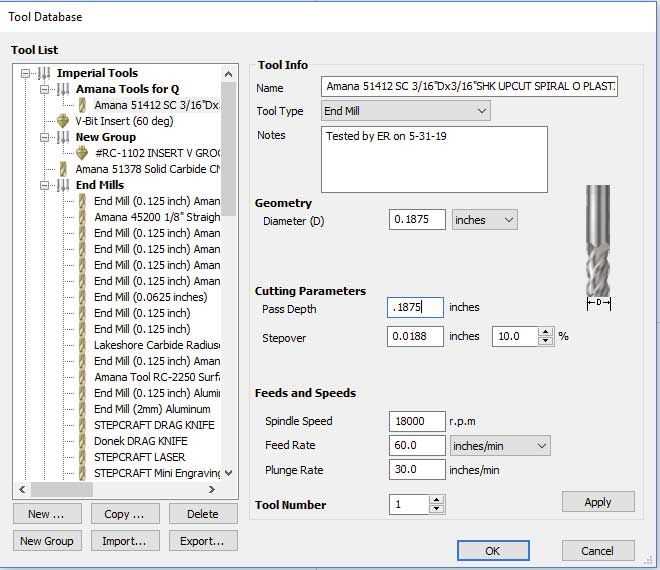

TAKING THE GUESS WORK OUT OF FEED AND SPEED SETTINGS We are very fond of Amana Tools and they are often our end mill of choice for many of our jobs. One common question that we get from our customers, and truth be told, we often ask ourselves is "What is the optimal speed and feed settings for the given tools that we are using?" There are many ways to go about this and from my experience the most common are: Start at safe speeds and increase as job runs using your "ear" as a gauge Asking online what other people suggest and hope for the best Starting with a guess based on improper understanding of the tools chip load parameters Run to point of the machine straining and making crazy noises and then back off a little Finding a setting in one material and then assuming you can use the same in every material Playing with settings and observing the "chips" that are produced for what looks optimal While you may have some success with any one of these, wouldn't you like to have a more reliable way to determine the best settings for your project? Yah, me too! Since we starting manufacturing the new Q-Series line of CNC machines, in which we have much more rigidity, speed and power at our disposal and it made no sense to use D-series (or desktop machine) settings on our production-grade machines just because they were "safe" and worked on the smaller machines. In many cases with the Q, we are able to run jobs as much as 5 times faster and at pass depths that are 2-3 times deeper. So we resolved with two solutions: Using the G-Wizard Calculator from CNC Cookbook (www.cnccookbook.com) Using Amana Tool's new Vectric tool file library The G-Wizard software is awesome and in our experience, it works perfectly every time. The only real issue is that there is a little learning curve to the program. However, we love it so much that we will detail the use of the program in video/blogs in the upcoming weeks. It is truly the ultimate solution to get the best results every single time. That being said, the focus of this article is on a very simple solution that anyone (using Vectric software) can use right away - the new Vectric Tool Library from Amana Tool. On just about every CNC tool on their website they offer a button in the description for "Vectric Library". When you click on this it will prompt you to download the file. This file can then be imported into your Vectric Tool Library and recalled whenever you want to use that tool again. How well does it work? Very! Is it perfect? No! But it is close The bottom line is that as long as your machine is rigid, these files will produce excellent results as you download them. Minor adjustments might have to be made for lighter duty machines. The files take into consideration the chip load specs for the given tool and, in most cases, using a fixed RPM of around 18,000. From there they will give you the optimal pass depth, plunge rate and feed rate for the tool. They basically take the guesswork out of the speed and feed dilemma . My Findings Many of the tool files that I run from Amana have a couple things in common. First, they are mostly set around 18,000 RPM. This is not an issue for just about any CNC, but that is the typical base line that I see in these files. Second, most of the tools will have the pass depth equal to the tool diameter. On the Q machines the pass depth is not a problem because the machines are very rigid and the spindle is powerful so I find that the settings are very close as given. However when I move the file to our D-Series machine, or to any lighter-duty CNC, the only real change that I find I need to make is in the pass depth. The RPM, Feed Rate and Plunge Rates are all good, but cutting the pass depth in 1/2 or even a little more usually provides excellent results. However, where the Q-Series can handle up to 3/4" shank tooling, the D-Series is limited to 1/4". So for a given 1/4" end mill that I might run on the Q with a 1/4" pass depth, I would run at 1/8" pass depth on the D. The only exception to this, from my experience, is when cutting non-ferrous metals like Aluminum, brass or copper. In these cases, I find that I need to cut the pass depth down quite a bit more from the file settings on the D-Series as usually I limit my pass depth to about 0.020" or so for aluminum. So the project will take a little longer to produce, but the quality and end result is the same. In Summary If you are a user of Amana Tools and a Vectric user, then you should be using the Vectric Library files that Amana provides. They save a lot of time and deliver excellent finish and tool life. If you are using a lighter duty machine, I would start with all the settings that they provide but reduce the pass depth to 1/2 of their suggestion or more depending on how light your machine is. I think you will find these files will save you a lot of frustration and give you the best possible results outside of using the G-Wizard software. LINKS G-Wizard Software

Amana Tools

Vectric Software

May 31, 2019

by

Stepcraft .Inc, Erick Royer

Easy Feed and Speed Solution - Thank You Amana Tool!