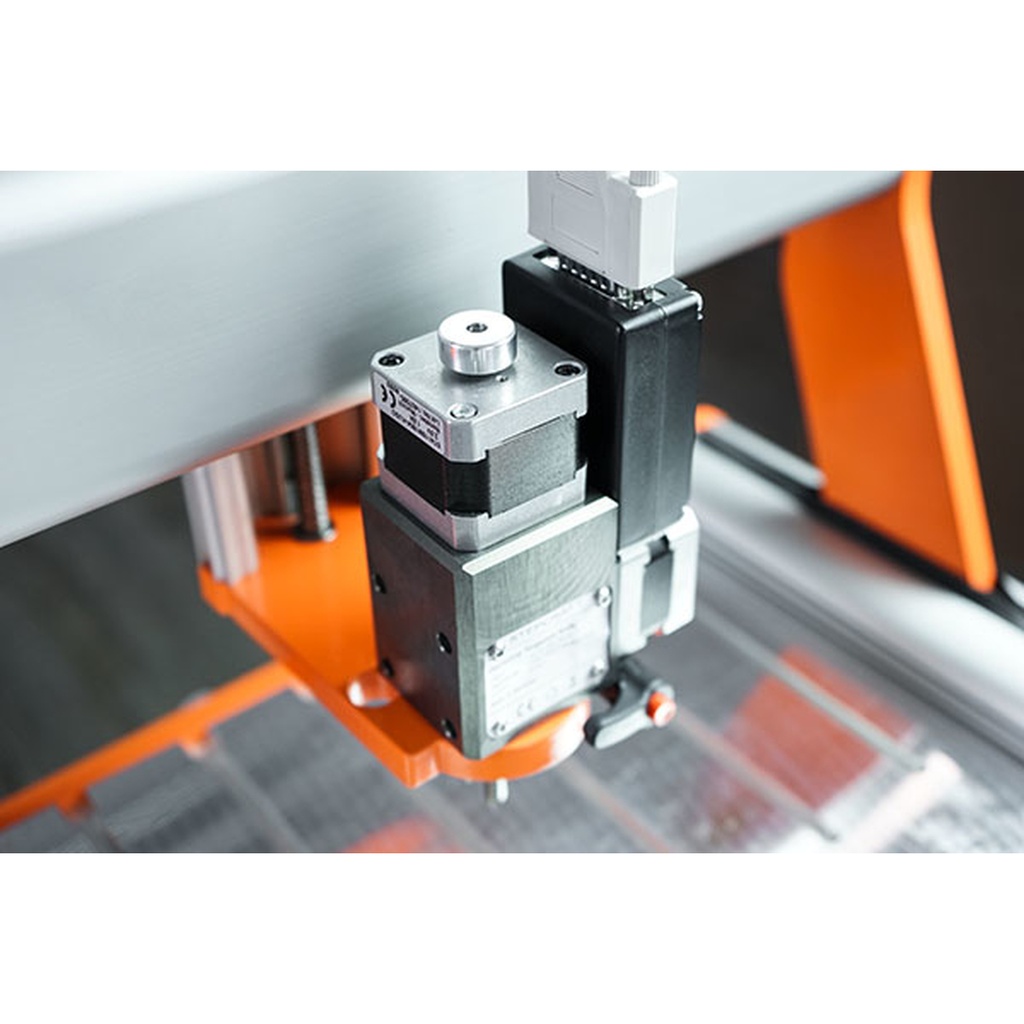

Oscillating Tangential Knife (OTK-3)

Description

Use the Oscillating Tangential Knife OTK-3 to cut a variety of different materials quickly and with high-precision. For this purpose, the tool is clamped into the tool holder of the CNC gantry milling system and controlled via the CNC control software. The powerful oscillation motor quickly moves the blade up and down while the actuator rotates the blade in the respective cutting direction. This way, the tangential knife provides highly accurate results even with small contours and letterings. The solid carbide blades are available in cutting depths from 6 to 25 mm.

*If you want to use your OTK-3 Knife with a Switch-Box, you MUST purchase the 2nd layer module add-on to enable it's connectivity and switch it on/off with the Box.

IMPORTANT NOTE: Solid carbide BLADES ARE NOT INCLUDED in the scope of delivery. Suitable blades can be found HERE

Technical Specifications:

- Stroke power knife: 90 N with maximal stroke rate

- Maximal stroke rate: 2600 stroke / min

- Oscillating mode: Grooving operation / 1300 strokes / 2000 strokes

- Stroke: 3,0 mm

- Shaft diameter tool: 6,0 mm

- Tool interface: Weldon shaft

- Dimensions: 98 x 52 x 160 mm

- Clamping diameter: 43 mm

- Weight: 1,08 kg (without knife, connection cable)

- Housing: Aluminum 7075 anodized

- Voltage: 30 V

- Control electronics: 5 V

Typical Materials:

- Sealing materials

- Corrugated cardboard / Solid boards

- Leather and cork

- Fabrics and foils

- Hard foam boards

- Carpet

- Depron

Included in Package:

- Oscillating Tangential Knife OTK-3

- D-Sub-15 connection cable

- 1 g special maintenance grease