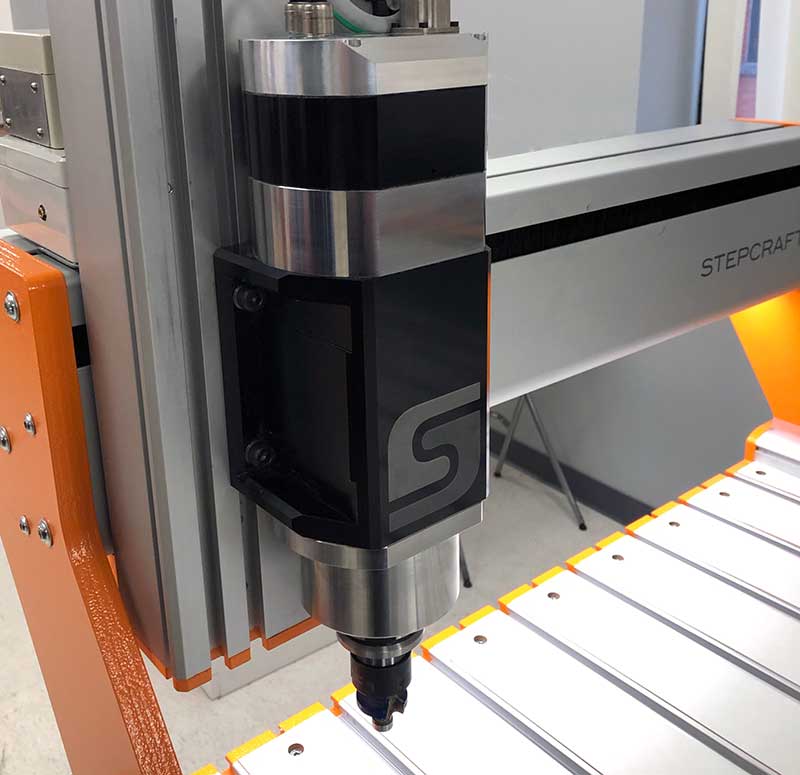

Q-Series ATC-2200 2.2kw Automatic Tool Changer Spindle (Option)

This product is no longer available.

Description

Get the most out of the Q-Series production grade CNC systems by adding a ATC-2200 2.2 kW Automatic Tool Changer Spindle. The ATC-2200 develops over 3HP, giving you more than enough power to process hard woods, plastics and non-ferrous metals. The unique passively-cooled design keeps the operating temperatures low (less than 105 degrees F) and is ultra quiet - all without the need for noisy fans or cumbersome and maintenance-intensive water-cooling systems.

The spindle is designed for the case to be fully pressurized, with the addition of a 1.5 CFM compressed air line - this is NOT required but can be used when working with very fine and gritty dust particles like carbon fiber. A 90 PSI compressed air line is required to activate the draw bar for the tool changes.

The Q-Series CNC will come equipped with the solenoid to actuate the tool changes, but if you plan to use on another brand of CNC, you will need to purchase a solenoid separately. The ATC-2200 uses industry-standard ISO30 tool holders. You can get these with either ER25 or ER32 collets (Stepcraft carries ER32 version).

The tool rack can be installed in 4 different positions on the Q-Series machines (front, back, left or right) to give you the maximum flexibility. When installed on the front of the machine you can maximize the number of tool holders in use and achieve the maximum Z-height (tool stick-out). You can install on the side of the machine in the Y Axis to allow the ability to pass through longer materials on the machine.

When used with UCCNC, our custom ATC software will allow fully-automated tool length calibration for any or all tools in the rack - simply tell the software how many or which tools to calibrate and the system does the rest. These tool calibrations will remain in memory for as long as you keep the tools in the specified locations.

FEATURES:

3HP 18,000 RPM 220V HF Spindle

Passively cooled (No fan, no water cooling)

Low operating temperature - < 130 Degrees F

Ultra Quiet

Uses standard ISO30 tool holders (Sold separately)

Case is fully pressurized

Dual ABEC7 (German-made) contact bearings

Zero maintenance (Uses permanently greased bearings)

INCLUDES:

ATC Spindle

Single ISO30 Tool Holder

Single ER32 Collet (1/4")

Hitachi NES-1 VFD (Single Phase 220V input)

REQUIRES:

Compressed air (110 PSI)